Posted to News on 23rd May 2007, 09:00

20% discount off top-of-the-range drill sharpener

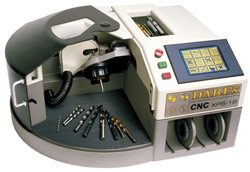

Kitagawa Europe is offering an introductory 20 per cent discount off the price of its top-of-the-range Darex XPS-16 CNC drill sharpener.

Described by the company as representing the ultimate in precision, simplicity and productivity, the XPS-16 combines sophisticated CNC four-axis sharpening of a wide range of twin-flute drill point types, with simple, one-touch operation.

The XPS-16's advanced CNC operation enables it to easily reproduce the complex, high-quality points found on today's premium HSS and carbide drills. Yet its easy-to-learn touchscreen interface allows even novice users to produce perfectly re-sharpened drill points in seconds.

Suitable for conical, four-facet, split-point and radius-split-point bits with angles from 118-150 degrees as standard – with a 90-118 degree add-on option also available – the XPS-16 sharpens HSS, cobalt and carbide drills from 3-16mm diameter and 50-220mm long. It has been designed specifically for heavy-duty use within busy machine shop environments and is easily capable of sharpening more than 400 drills per day.

Operating the XPS-16 could not be easier. A blunt drill is first inserted into the sharpener's chuck and the required drill point type selected using a simple touchscreen panel. On initiation of the sharpening cycle, three independent electronic sensors automatically detect the drill's length and diameter, precisely locate the cutting edge, and calculate the web thickness. The unit then sharpens the drill and applies the required split point form, in one seamless operation. The XPS-16 will also hone carbide drill edges as part of the automatic process – thereby extending tool life and maximising drill bit machining accuracy.

Long-life wheels

The machine is equipped with CBN and Diamond wheels that are designed to sharpen 2000-4000 drills. Metal removal is set at a minimum to extend drill life. However, this can be overridden by up to 0.50mm if necessary to compensate for gouges or nicked drill edges.

User-specific drill sharpening programmes can also be created easily and stored for future use. The machine also incorporates Darex's latest 'Grind Motion Control' system, which detects excess material on the blunt drill bit. This enables the grinding feed rate to be adjusted automatically, both to prevent burning and to provide optimum sharpening performance.

The unit's long-lasting super-abrasive plated grinding wheels and lifetime-lubricated seals ensure low maintenance and a long service life. Furthermore, the sharpener incorporates a vacuum filtration system to eliminate grit and airborne contaminants such as carbide dust. In addition, its computerised controls are backed by advanced diagnostic software that alerts operators to potential problems during the sharpening cycle.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>