Posted to News on 18th May 2016, 13:57

Avoiding overflow with light section sensors

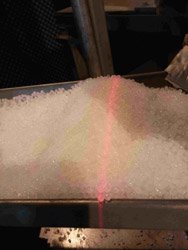

Light section sensors from Leuze electronic monitor fill levels in the plastics processing industry.

If the infeed overflows in a system that processes plastic granulate, the drive can be damaged and the entire process may come to a standstill. The work and expense would be immense.

The Israeli electronics manufacturer Galoz electronics Ltd. therefore implemented a compact and highly integrative optical monitoring system for a global leader in the development and manufacture of high-quality additives, mixtures and coloured plastic granulates for the plastics processing industry whose products are used in injection moulding applications. These granulates form the basis for plastic parts in the automotive industry as well as for garden furniture and household appliances.

The task was to monitor the correct fill level of the granular raw material in the supply line to the shredder. Overfilling would damage the main drive and result in system downtime as well as large repair costs. The company had not previously found a way to reliably and intelligently monitor the supply line. Moreover, direct networking between the supply and discharge was lacking. In the case of a slower discharge, excessive fill levels and overflow in the supply channel occurred time and again. The raw material came into contact with the warm main drive motor and melted. As a result, material could penetrate the interior of the drive, which then failed.

The responsible equipment supplier, Galoz electronics Ltd, found a solution to this problem - with the LRS 36 light section sensor from Leuze electronic. With its two digital outputs, both tasks can be performed reliably and efficiently: the determination of the correct level and the signalling of a possible granulate overflow. An infeed control was created that can also initiate a possible shutdown in order to avoid damage to the system.

LRS 36 switching light section sensors in three models - teach, as area sensor with and without background suppression and as multi-track completeness monitoring device ("track scan") - can now be conveniently taught-in and configured directly on the device with a new teach function. Similar to light barriers or light scanners, the area sensors detect objects at any position within their detection range at distances of up to 800mm. These sensors are thus suitable for economical object detection. The object size to be detected can be preset in three levels (fine, medium, coarse).

With the new teach function, extensive commissioning and configuration via the PC are eliminated. Nevertheless, the configuration defined by means of teaching on the device can be read in by the LRSsoft software and further edited in greater detail.

Line range sensors from Leuze electronic do not operate with individual light spots; instead they project a divergent light beam using laser line illumination. The transmitters and receivers are housed together in a compact, easy-to-install unit. Where elaborate sensor systems, sensor combinations or additional evaluation units were once necessary, the light section sensors from Leuze electronic, with their large measurement range, constantly open new fields of application.

Go to www.leuze.co.uk for more information about Leuze's light section sensors.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

1B Fenice Court

Phoenix Park

Eaton Socon

PE19 8EW

UNITED KINGDOM

+44 (0)1480 408500