Posted to News on 6th Feb 2025, 09:51

Background Suppression Photoelectric Sensors perfect for cheese Packaging

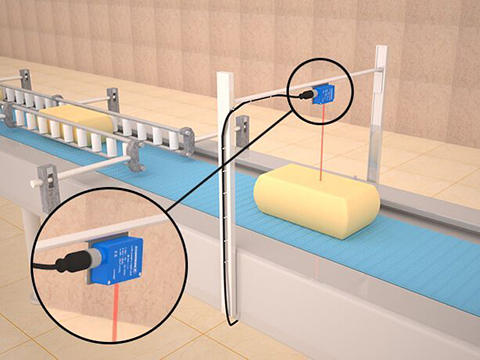

To increase the capacity of a packaging line for individually packaged cheese portions, a manufacturer required a robust, reliable solution to detect the presence of each cheese portion to control the speed of in-line buffering units. These feed a packaging machine, in a high-volume, hygienic production facility. The company turned to Contrinex for a solution.

(See PLUS Automation at FoodManufacturing.Live, 15 October 2025, on stand 48)

Once cut to size, cheese portions travel on a food-grade conveyor to a packaging station; the duration of the packaging cycle is dependent on the type of cheese and the portion size.

Prior to end-of-line packaging, a buffering station is used to produce a regular flow of portions with a predetermined spacing to optimise the packaging machine's throughput. The two operations must be synchronised, so the manufacturer required a sensor system that detects the presence of each cheese portion as it leaves the buffering station, triggering the packaging cycle.

Detection sensitivity parameters for each portion type and size are sent to the sensor for each production batch using IO-Link. This remote configuration eliminates the requirement to sanitise the sensor after a manual adjustment of the sensor.

Sensors must be food-grade certified and withstand the aggressive cleaning agents used during washdown routines. They must also accommodate the full range of portion sizes without the need for manual adjustment to minimise the changeover time between product batches.

Diffuse-mode photoelectric sensors with Background Suppression from Contrinex's C23PA family of sensors where selected as being ideal for this application.

The tiny cubic sensors are mounted above product conveyors immediately before a buffering station to detect the presence of cheese portions as they pass underneath. The Background Suppression feature enables the sensor to measure the distance to the fast-moving conveyor and ignore or suppress it so that the sensor is not falsely triggered by movements in the conveyor, for example, if it jumps upwards slightly.

Mounting the sensors was simplified, and savings were made by using Contrinex's range of stainless steel mounting brackets specially designed for this family of sensors. The sensor's industry-standard PNP normally-open output and M8 connector made installation and integration easy.

IO-Link the standardised point-to-point serial connection protocol for sensors and actuators, which is enabled on PNP versions at no additional cost, provides the advantages of digital communication without the need for special cabling. A second output provides a stability alarm in the event of reduced sensitivity, flagging the need for preventative maintenance before any performance degradation occurs.

The small (20mm x 30mm x 10mm) robust sensors provide reliable operation in the demanding washdown environment. They are rated to IP67 and Ecolab-certified. An operating range between 15mm and 250mm, adjustable via a teach button or via IO-Link, accommodates the range of portion sizes without compromise.

A brief one- or two-step teach procedure simplifies the initial set-up of the sensor. If a new portion size is introduced, process engineers can teach the target object and, optionally, the background. Once taught, sensitivity parameters are stored on the sensor's inbuilt memory and may be retrieved or updated remotely via IO-Link, eliminating the need for manual adjustment.

The C23PA family of sensors covers all sensing technologies including a choice of both visible and UV-based transparent-object-detection.

The C23PA family of photoelectric sensors, offers 5 sensing technologies, being Background Suppression, Diffuse, Reflex, and Through-beam, plus Transparent Object Detection using either conventional visible-light or uniquely, Ultra-violet illumination.

The sensors are available with choices of PNP/NPN, Light-on/Dark-on, Cable or Socket, and can be adjusted using a teach button or IO-Link.

They exceeded the customer's need for reliable operation with little or no manual intervention and so were highly cost-effective. The choice of 4 different low-cost stainless-steel mounting and protection brackets simplifies installations, which can create significant cost savings.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>