Posted to News on 4th Sep 2012, 10:21

Customised linear motion systems match application requirements

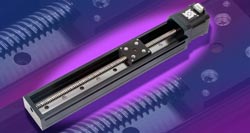

Reliance Precision Mechatronics now has the capability to manufacture customised linear motion systems for many different types of application. One example of the customisation capabilities to meet a unique engineering requirement is a precision linear rail system developed for an application requiring very high stiffness, accuracy and repeatability.

Along the axial length of the system is a precision recirculating ball rail, which has a high load capacity and high rigidity. The extruded aluminium frame supports all the components for the system. In this particular design, the drive mechanism is a Haydon stepper motor and a precision rolled 303 grade stainless steel Kerk lead screw. Attached to both the lead screw and the precision ball rail is a machined aluminium load carriage with an integral Delrin drive nut.

The rail system can be easily tailored to suit many alternative applications. The design of the rail mechanics allows a maximum load of 1570N in the Z direction while maintaining the accuracy specification. Maximum roll, pitch and yaw specifications are 22.65Nm, 13.9Nm, and 13.9Nm, respectively. The practical load capability will depend on the motor and lead screw. The system has been designed around a 9.5mm diameter lead screw using standard leads of 0.64mm to 38.10mm.

When combined with a 1.8-degree hybrid stepper motor, very fine positioning resolutions can be configured. A brushed or brushless DC motor also can be used for applications requiring higher speed and higher linear force output. Positioning resolution in the case of a closed-loop DC brushed or brushless motor is determined by the capabilities of the encoder system. An encoder system can be added to either the motor or the lead screw.

For applications requiring even greater accuracy than can be accomplished with a rotary encoder, the rail system has features added to allow the integration of a linear encoder with micron resolution for feedback of the true load position.

For more information on the full range of Reliance's positioning components, assemblies and customisation capabilities, go to www.reliance.co.uk.

Rowley Mills, Penistone Road

Lepton

HD8 0LE

UNITED KINGDOM

+44 (0)1484 601002