Posted to News on 8th Jan 2011, 12:06

DMG selects Schaeffler linear bearings for machine tools

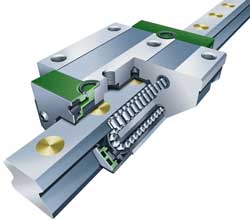

DMG uses Schaeffler's high-performance RUE-E linear recirculating roller bearing and guideway assemblies for its machine tools, as well as other linear and rotary products from Schaeffler's INA, FAG and IDAM brands.

In the machine tool industry, system partnerships and co-development projects between OEMs and component suppliers are now increasingly important. Machine tool manufacturers prefer to focus on their core competence and source ready-to-fit components and sub-systems from technology partners. The result is that all parties involved benefit from this close co-operation, including the manufacturers, component suppliers and end users.

German machine tool manufacturer Deckel Maho Gildemeister (DMG), for example, is working closely with The Schaeffler Group's INA Linear Technology division on a number of new machine tool developments. When it comes to linear guidance systems for its large and super-sized milling centres, DMG relies exclusively on Schaeffler's high-performance RUE-E linear recirculating roller bearing and guideway assemblies.

The RUE-E linear guidance system provides smooth, uniform running characteristics and high dynamics for precision linear movement of heavy loads. The range is modular, so customers can select from a range of accessories to suit their application.

In addition, the range benefits from Schaeffler's patented injection moulding technology, which enables 'perfect' rolling element guidance in the load and return zones, optimised transitions and the best possible running characteristics with very low stroke pulsation. Schaeffler has also reduced the number of components in the design, resulting in more robust, reliable rolling element guidance.

Sealing

Labyrinth seals on the rolling element recirculation system improve protection against contamination. Uniform lubrication is also guaranteed due to a completely closed and sealed lubrication duct.

The design of the guides also incorporates an efficient sealing concept, comprising single-lip upper seals, double-lip lower sealing strips, and double-lip end wipers. The end plates fitted as standard in front of the contact end wipers provide extra protection against coarse contaminants, which means the contact end wipers retain their full performance capability even in environments with fine, often aggressive contaminants.

DMG has been working with Schaeffler to develop linear guidance systems for its DMU/DMC 200 to 340 milling centres, including five-axis machining centres. Depending on the size of the machine tool and the loads acting on the main axes, linear recirculating roller bearing and guideway assemblies in sizes RUE 35, 45, 55 and 65 are specified. In addition, in order to meet specific customer requirements, DMG uses covering strips, double-lip wipers and customised sealing kits from Schaeffler's modular KIT system. These are pre-assembled at the factory. Load calculations are carried out using Schaeffler's Bearinx calculation software, complemented by DMG's own design calculations for further system refinements.

Lubrication

Optimised distribution of lubricant for the RUE-E units ensures minimal grease consumption of just one litre per year using machine lubrication intervals of four hours. Additional components are not required.

Due to extremely high axial loads on the milling centres, Schaeffler supplies DMG with selected combinations of guideways and recirculating roller bearing units. These precisely matched pairs are combined to achieve minimal waviness in the guideways and maximum accuracy of the carriages. All key data is recorded in test documents.

The RUE-E units are supplied fully assembled and well protected in special returnable containers, which minimises the risk of damage or product mix-ups. Prior to installation, DMG inspects the machine parts on which the linear roller bearing and guideway assemblies are to be installed with extreme accuracy, examining them for compatibility with the linear guides.

Schaeffler's partnership with DMG is not limited to linear technology. Under its INA, FAG and IDAM brands, Schaeffler offers a comprehensive range of products for machine tools, including drive technology, bearings for main spindles and feed spindles, as well as all rotary axis systems.

For more information on Schaeffler's range of linear guidance systems for machine tools, call the Marketing Department on +44 (0)121 313 5870 or email [email protected]. Follow the link for more information about RUE-E linear recirculating roller bearing and guideway assemblies.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>