Posted to News on 29th Mar 2016, 19:33

Dual volumetric rotor pump for latest generation adhesives

The development of new adhesive technologies has led to unique capabilities in the field of bonding. Take LOCTITE 4090 as an example. This 2-part hybrid has the speed of cyanoacrylate or superglue, the ability to bond almost any combination of substrates and the high temperature and chemical resistance properties of an epoxy. These performance characteristics offer interesting opportunities in product design but what are the considerations in the production environment?

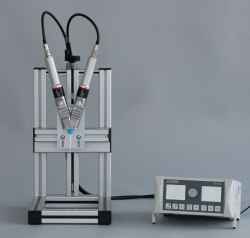

A precise and repeatable mixing ratio is critical for this new generation of 2-part adhesives and this is why the introduction of the new MM25 Volumetric Dual Rotor Pump is so important. It allows manufacturers to take full advantage of the new adhesives in semi- or fully automated production.

This dispenser uses positive displacement technology to ensure consistent dosing. It is based on two eccentric rotor pumps the main components of which are a stainless steel rotor that rotates within a self-sealing elastomeric stator. The elastomer has the highest chemical resistance on the market, allowing the pump to be used universally. As it dispenses the adhesive volumetrically and virtually free from pulsation, it gives far greater control over the amount of adhesive released; accuracy is +/-1 per cent.

The volume flow depends on the size of the pump and the number of revolutions; direction of flow is reversible to eliminate the possibility of post-dispense dripping. As flow is directly proportional to the speed of rotation, the system allows for the continuous, variable adjustment of the dispense rate via the motor. The option to upgrade the system with two additional pressure sensors provides even greater process safety.

MM25 is suitable for handling low and high-viscosity materials with ratios of 1:1 to 10:1. Two separate servo drives allow continuous adjustment of the ratio mix and the system can also process some abrasive products.

The pumps can be fed directly from the MM30 400ml Dual Cartridge Applicator that provides independent control of the feed from each of the two adhesive components. This system has been widely proven across the globe for dispensing a vast array of two component adhesives therefore ensuring an accurate, reliable and robust production option.

For more information about the MM25 Volumetric Dual Rotor Pump and other products, please go to www.loctite.co.uk.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>