Posted to News on 29th Nov 2022, 09:18

Durable drives for belt conveyor systems

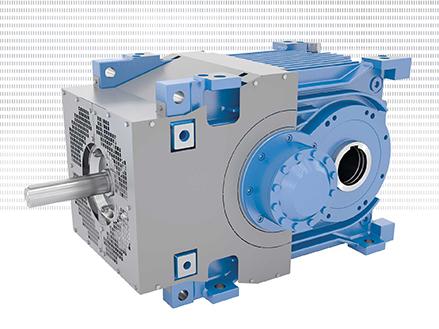

With high thermal limit powers, MAXXDRIVE XT industrial gear units from Nord Drivesystems have been optimised for bulk logistics applications such as belt conveyor systems.

Conveyor technology drives in the bulk goods and mineral industries demand high thermal and mechanical load capacities, and long service life. The MAXXDRIVE XT provides output torques of 15 to 75 kNm with speed ratios from 6.3 to 22.4 and is offered in seven sizes for powers from 22 to 2,100 kW.

The power and speed ranges of the two-stage right-angle gear unit have been specially designed for industries in which low speed ranges are required in combination with high powers – such as the bulk goods and mineral industries. Its robust design makes the MAXXDRIVE XT resistant to dirt and reliable in rough operating conditions. A special sealing concept reduces maintenance. Large roller bearings and centre distances increase the load capacity and service life of the components.

As standard, the industrial gear unit is equipped with a heavily ribbed UNICASE housing and an integrated axial fan. Due to the increased surface and the airflow covers, the cooling airflow is optimised and a very high thermal limiting power is achieved. In many cases, additional cooling is not required.

“As with other application areas, our drive solutions for the industry are individually configured for customers according to the modular principle”, emphasises Jörg Niermann, head of marketing at Nord Drivesystems. This is based on a comprehensive range of frequency inverters, motors and gear units, as well as coupling and brake systems, each with a wide variety of options. Features such as hydraulic couplings tailored to the particular process or Taconite seals, which effectively protect radial shaft seals against abrasive dust and corrosion, ensure smooth operation.

Nord also offers innovative predictive maintenance concepts for heavy industrial gear units. Nord drives networked via the frequency inverter communicate their status data via the control system or directly into a secure Cloud. With optional vibration monitoring, condition changes can be detected at an early stage and predictive maintenance can be scheduled in good time. Performance data recording also ensures optimal system dimensioning as well as continuous condition monitoring of the drives.