Posted to News on 2nd Nov 2022, 14:00

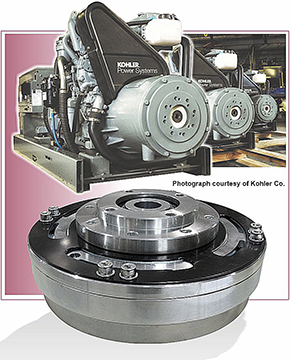

Electromagnetic clutches for marine and hydraulic pump applications

MMC series electromagnetic clutches from jbj Techniques are designed for use with hydraulic pumps, many of which are used in marine winch drives. Typically flange or plate mounted, they engage and disengage the pump.

These mobile electric clutches provide reliable performance in many long life applications where electromagnetic clutches are key. They were primarily designed as air conditioning compressor clutches, but now are also used as clutches for hydraulic pumps (clutch pump), water pump clutches, electromagnetic fan clutches and clutches for vacuum pumps.

The units that are used to clutch hydraulic pumps and to clutch water pumps are typically used for tow trucks, marine winch drives and boom trucks in the utilities industry. Water pumps are typically driven by our clutches from a gas engine on such equipment as pressure washers, street sweepers and carpet cleaning trucks.

Additionally, pump clutches are often used in vacuum pump and compressor applications such as refrigeration and waste removal trucks as well as mobile service trucks, or engine compartment applications where the clutch engages a compressor mounted in the engine compartment of a service truck. Ogura mobile clutches range in size from 78.64 to 2033.73 Nm (58 to 1500 ft.lb.) and feature numerous pulley configurations including v-belt and poly-v as well as universal hub mounts. The user can choose from a straight, splined or tapered bore to match the corresponding pump shaft. Many of jbj’s pump and compressor clutch configurations are interchangeable with both Pitts and Warner Electric.

Mobile clutches are made up of three major sub-assemblies:

- Field assembly: This is the coil and backing flange which provides the magnetic flux that makes the clutch engage.

- Rotor assembly: This includes the pulley and the bearing and is normally the input of the clutch.

- Armature assembly: This includes the armature disc, springs and hub and is normally the output.

The field is mounted to a stationary member such as a support bracket of a pump. The rotor is driven by the belt from the engine and rotates constantly. When the clutch is energized, the armature pulls against the rotor and drives the shaft of the pump.

Engagement of the armature to the rotor is caused by the magnetic attraction between these two elements. When direct current is applied to the field, the magnetic flux is transferred from the field into the rotor and then into the armature. The slots in the rotor and the armature are called banana slots. These slots allow the flux to contact the rotor and the armature in more than just two places (a normal magnet has only two points – north and south – of attraction). By making multiple points of flux connection, the torque of a clutch can be increased.

A standard mobile clutch has two flux paths. This is called a double flux, or a four-pole design. To disengage the clutch, the voltage going to the coil is simply turned off. Once the voltage is released, the springs between the armature and the hub pull the armature away from the rotor, creating an air gap so no contact is made.

28 Trowers Way

Holmethorpe Industrial Estate

RH1 2LW

UNITED KINGDOM

+44 (0)1737 767493