Posted to News on 1st Oct 2014, 11:27

Energy-efficient palletising with ecoSTACK

R. A. Rodriguez is promoting its IEF Werner ecoSTACK palletisers. Automation is increasingly helping manufacturers to contain costs and assure consistent quality. To maximise these gains, however, it is vital that the automated systems are as energy efficient as possible.

Users of IEF Werner ecoSTACK palletisers can be assured this brand is one of the most energy efficient available. Unlike other palletising systems, ecoSTACK does not require compressed air, therefore power consumption can be less than 20 per year based on single shift operation. It is also designed to power down system components automatically when they are not in use.

The ecoSTACK palletiser is able to process pallets of different sizes between 300 × 400 × 20mm and 400 × 600 × 150mm. The system can accommodate loaded pallets with a combined weight of up to 60kg. Multiple ecoSTACK systems, working in unison, can also be used to simplify complex processes. For example, they can be employed to separate good and reject parts or parts that need to be re-worked.

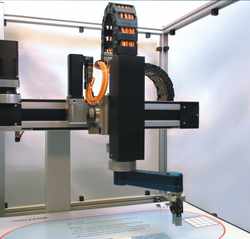

For flexibility, ecoSTACK can be fitted with the IEF Werner rotaryARM that has a range of 399mm and can provide continuous rotation. The combination of ecoSTACK and rotaryARM provides a very fast pick and place system for any application that requires effective and precise automation.

Most applications require bespoke tray designs and gripper technology, but IEF Werner palletisers are also available with a wide range of standard accessories to optimise the handling process. These include gripper rotation, multiple grippers, reversing units, and alignment systems.

In the construction of its handling systems IEF Werner applies a simple rule: the lower the mass, the quicker it moves and the less power it consumes. The Module 55 ZOM that provides Z-axis movement in these systems is a typical example. Its comparatively heavy motor is mounted externally to the unit and due to this weight reduction cycle time is typically reduced by up to 15 per cent.

Typically IEF Werner palletisers are used for handling medical, electronic and automotive components with many proven applications at global manufacturers. For further details please go to www.rarodriguez.co.uk.