Posted to News on 14th Oct 2015, 18:43

Festo extends Optimised Motion Series electric positioner range

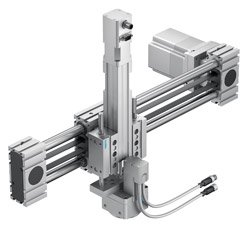

Festo is adding three new actuators to its Optimised Motion Series (OMS) of electrical positioning systems. These cost-effective and simple-to-use products have been designed to allow machine builders and system integrators to improve both motion control and their profit margins for products such as light assembly applications, baggage inspection systems and handling of liquids and specimens in laboratories. Festo's OMS family aims to offer the the performance of electric axes with the simplicity of pneumatics.

The first new product is the EPCO guided electric cylinder (EPCO-G) that provides for simple positioning with strokes of up to 400mm. With an integrated guide unit, the EPCO-G can withstand high axial and radial loads, which means it can be utilised in a wider selection of handling systems.

Available in three sizes (16, 25 and 40), the cylinder can achieve speeds up to 500mm/s and it provides high stiffness in a low-weight system, giving high performance over a long service life. Furthermore, it has lifetime lubrication so it is maintenance-free. Mounting and installation are also exceptionally easy, meaning that engineers can save time and costs associated with set-up and maintenance. The guide unit can also be ordered as a single unit for easy retrofitting to existing EPCO cylinders.

The second new addition to the OMS product family is the ERMO electric rotary drive that meets the same high performance criteria as Festo's previous rotary drives but at a more attractive price. Suitable for compact process stations and pick-and-place applications due to its angle flexibility and rotation capabilities, the ERMO is easy to commission, allowing machine builders to 'plug and work' instantly.

With a maximum angular velocity of 600deg/s, torque of 5Nm and repetition accuracy of between +/-0.05deg and +/-0.1deg, the ERMO electric rotary drive can be used for a range of rotating, placing, turning and pivot drive handling systems.

Nigel Dawson, the electric drives product manager at Festo, says: "The large diameter of the bearing allows for high offset loads to be carried reliably, and centre a through-hole allows cables and tubing to be added with ease. The ERMO has the same interface as a pneumatic rotary actuator, meaning all parts can be assembled seamlessly, saving both time and money for machine builders and engineers implementing new systems."

New belt drive axis

Finally, the ELGR linear belt drive axis is now available with a highly corrosion-resistant chrome rod and bearing material, meaning it provides a reliable and robust option in more arduous environments. The ELGR is an exceptionally cost-effective product for feed forces up to 35kg, and is available as a completely mounted sub-assembly, enabling machine builders to save time and costs with commissioning and set up. A cost-effective motor package also comes as part of the axis, making this system suitable for a wide variety of handling applications where simple linear movements are required.

All products in the OMS product family can be easily mounted together to create a complete two-, three- or four-axis handling system that can be best adapted for each user's individual requirements, enabling them to build efficient and reliable machines.

Nigel Dawson concludes: "These three OMS additions open up the market between pneumatic actuators and electric drives. Combining the simplicity of pneumatics with the quality performance of electric drives, engineers across many industries can enjoy a range of benefits. These products are all simple to commission, requiring no special software, and can be delivered together with one single part number, making the ordering and delivery process a simple one for all involved."

For more information on the ECPO-G, ERMO or ELGR additions to the Optimised Motion Series (OMS) of electrical positioning systems, go to www.festo.co.uk/oms.