Posted to News on 11th Apr 2019, 12:47

HBM measurement system is user-friendly and time-efficient

When researchers at NEDO and MagHEM (Japan) wanted to develop a magnetic motor with 40 per cent less energy loss, they turned to HBM to provide a measurement system that could provide synchronised data in real time.

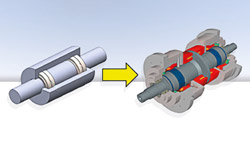

As part of its recent research project to develop a 'super' motor that uses new magnetic materials to reduce energy losses and increase power density by 40 per cent compared with conventional electric motors, The Japanese New Energy and Industrial Technology Development Organisation (NEDO) and Motor and Magnetic Materials R&D Centre (MagHEM) recently turned to HBM to provide a system that could provide synchronised data in real time, which was an important issue for further development of the motor.

The problem

As energy prices continue to rise, manufacturers are realising the importance and benefits of promoting better energy-efficient motors, such as improved reliability and reductions in repair costs and subsequent downtime. In addition, as many industrial organisations seek ways to demonstrate their concern for the environment, one way is to establish and implement a policy to use high-efficiency motors while, at the same time, conserving energy and saving money.

The solution

With this in mind, NEDO joined forces with MagHEM to develop a new efficient motor with 40 per cent less energy loss.

Previously using a conventional system to measure electrical efficiency, the procedure involved the use of a torque meter, power meter and multiple measuring instruments. However, that meant testing was relatively slow and quite time-consuming.

The result

In order to simplify this process, and without compromising on reliable data, NEDO and MagHEM opted to integrate the HBM eDrive testing system, complete with the dynamic GEN7tA power analyser, into its test bench.

HBM eDrive Testing is the revolutionary system for testing electrical inverters and electrical machines. Mechanical signals (eg torque) and electrical signals (current, voltage) are acquired simultaneously, helping to better understand the electric drive and its losses in minutes rather than days. This is important for the optimisation of the drive as well as the increase in efficiency.

By synchronising the measurement of all parameters, the measurement process was substantially simplified for NEDO and MagHEM's research and it also greatly improved test efficiency, as real-time computation enabled simultaneous observation of measured waveforms, such as magnetic flux and torque waveforms, as well as computed waveforms, such as iron loss separation.

As iron-loss separation requires data in the switching frequency range of the inverter, high-speed sampling is necessary. However, with the conventional system, not only was sampling slow but it was also impossible to capture the phenomenon in the relatively high-speed regions in order to investigate torque ripple or switching frequency related issues. To combat this, the HBM eDrive system was able to measure voltage and current signals with high speed sampling of 2MS/s and provide half-cycle power measurement calculations.

Furthermore, unlike the conventional technique, which meant that only analysis based on the averaged calculation results was possible, the HBM eDrive was able to process accurately all the raw data at high speed, with the added option of a Genesis HighSpeed 1000V input card to directly measure a high voltage of 600V.

As output can be quickly viewed on one screen as opposed to switching between the time-axis and the FFT display, the new system also offered researchers ease of use and was a welcome alternative.

For further information go to www.hbm.com.

Millbrook Proving Ground

Station Lane

MK45 2RA

UNITED KINGDOM

+44 (0)1525 304980