Posted to News on 28th May 2024, 11:00

High power density thanks to cycloidal design

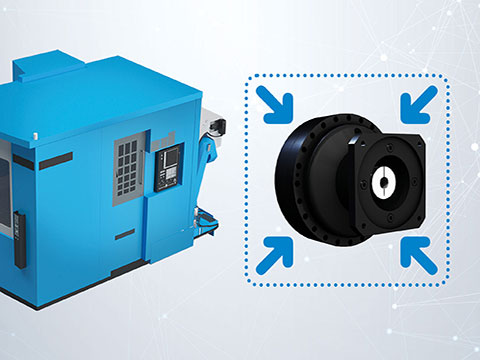

Nabtesco says its precision cycloid gear and drive solutions deliver exceedingly high power density paired with maximum reliability in an exceptionally compact design, making them ideal for use in demanding automation tasks.

Nabtesco's gear systems are characterised by high dynamics and precision (hysteresis loss 0.5 to max 1 arcmin) and low wear over their entire service life, thus making a significant contribution to streamlining machining processes, improving product quality and increasing productivity.

The high torque density allows for an extremely compact design. While designed to be particularly lightweight and space-saving, the precision gears are also immensely powerful, turning them into an ideal solution for all applications that call for a combination of maximum power and the smallest possible size.

The design allows the cycloidal gears to provide high reduction ratios with merely two or three gear stages - and without the need for the additional pre-stages that are commonplace in standard planetary gears. By design, Nabtesco says they are also considerably more rigid and compact (approximately 50 % shorter) and weigh less than multi-stage planetary gears. What is more, they offer outstanding resistance to shock loads (up to 500 % of the rated torque).

The compact design matched with the high performance density pay off for the user. Nabtesco gears afford the user increases in efficiency and performance. Better still, they can be installed in robots, machines and systems of smaller size. That has a positive effect on the consumption of power and resources, as well as overall operating expenses.

Especially the user-friendly solid shaft gears of the series Neco (servo gears with a modern, clean design) and NecoHT (high-torque gears for heavy-duty applications) set high standards in terms of precision, repeatability and smooth operation, design, corrosion protection, motor connection and modularity.

Instead of using a separate interface to connect each motor type, a system boasting modular sleeves and flanges guarantees easy adaptation of all standard servo motors. This guarantees maximum flexibility, a simpler configuration, and faster assembly with shorter delivery times.

Hollow shaft gears

Available as coaxial (RDS-C), parallel shaft (RDP-C), or bevel gears (RDR-C), the hollow shaft gears of the RD-C series can be used for a wide variety of applications. The large hollow shaft offers sufficient room for convenient and space-saving routing of cables and hoses - such as data and supply lines - through the centre of the cycloidal gear unit. It does not remain rigid, but rather is designed to rotate at the output rpm. The advantage of this is that a sensor on the hollow shaft can determine the position of the drive shaft.

Omnidirectional drive system

Nabtesco developed the fully integrated, decentralized drive unit with a Mecanum wheel specifically to accommodate the needs of mobile automation solutions. The RV-W Mecanum wheel drives used by Nabtesco also allow for high torque capacity in a compact design and are equipped with an integrated main bearing for optimal absorption of the radial and axial forces generated.

Maintenance-free operation of the compact and extremely robust drive concept is ensured thanks to cycloidal gears. The wheel unit houses all necessary components. This gives the user maximum freedom in the design of AGV solutions.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>