Posted to News on 15th Jun 2021, 08:58

Higher capacity split roller bearing launched

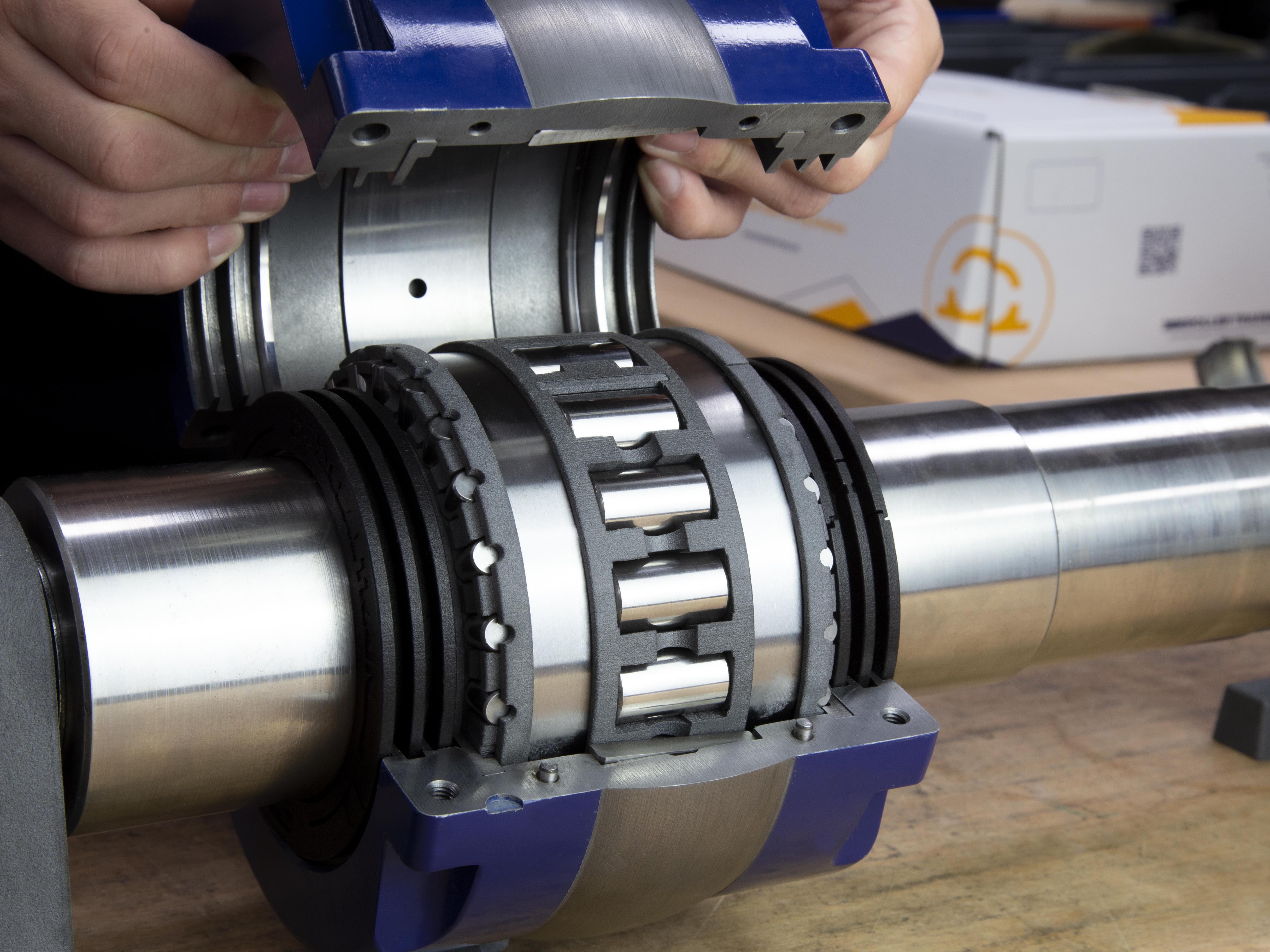

Bowman unveils split roller bearing with higher radial and axial load capacities

Described as ideal for higher load applications across all heavy-side sectors, Bowman’s new Advanced Split Roller Bearing is said to offer up to 75% higher radial load capacity and up to a 1000% increase in axial load capacity in both directions.

Technical director Ian Breeze had this to say on the significance of this latest innovation: “For the first time, plant builders and maintenance engineers can specify a split roller bearing that does not rely on race lips alone to accommodate axial force in high-load applications. The new Bowman Advanced Split Roller Bearing comprises two independent 3D-printed axial bearings designed to accommodate greater loads, improving system performance, with less maintenance and reduced unplanned machine failure.”

Surpassing performance expectations

When creating this bearing, Bowman believed it could surpass performance expectations in every way, Breeze adds, “so we integrated a patented triple labyrinth extended seal, which not only offers a tighter seal than other split bearings, but also reduces the need for costly removal, machining or replacement of worn shafts. Instead, engineers can simply fit an extended seal onto an undamaged part of the shaft, without compromising performance and without the need for extended downtime.”

Thanks to its high thrust capacity and increased radial load capacity, this bearing can be specified to replace solid spherical roller bearings in rotating machinery, he adds, delivering up to ten times faster bearing change times than previously possible for these applications. “When space is limited, engineers often need to disconnect the coupling and move other equipment, such as motors, gearboxes or pumps, out of the way before they can slide solid bearings off the shaft for replacement or maintenance.

Maintenance and replacement much faster

“Split roller bearings can be assembled radially around the shaft, eliminating these additional logistical challenges, and making maintenance and replacement a lot faster and more cost-effective. To further enhance time and cost savings, the Bowman Advanced Split Roller Bearing uses the rollers to lock the two cage halves together, eradicating the use of small and easy-to-lose clips and other locking components.”

The new bearing design also claims a range of additional installation and performance benefits, such as larger diameter screw sizes to accommodate increased capabilities for the clamp rings, cartridges and pedestals and roller pockets, with cavities to hold the grease against the rollers.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Bowman International Ltd (incorporating Oilite Bearings)

10 Isis Court, Wyndyke Furlong

Abingdon Business Park

OX14 1DZ

UNITED KINGDOM

+44 (0)1235 462500