Posted to News on 28th Mar 2014, 10:28

How to design state-of-the-art electrohydraulic drive systems

This article from Hydac Technology Ltd outlines some of the considerations when designing state-of-the-art electrohydraulic drive systems, and the techniques to apply.

Electro-hydraulic drive systems are used to power everything from robots and presses to elevators and automobiles. Designing state-of-the-art systems is actually a multi-faceted process that can take years to accomplish fully. A number of techniques can be used in order to make the planning process much smoother, as outlined below.

What to consider

When planning an electro-hydraulic system, several things should be taken into consideration. For example, how other moving parts such as valves, pumps, and cylinders all behave, as this will affect the overall design of a system. Also think about different operating variables such as acceleration, pressure, speed of operation and the flow of liquid or other materials. All of these things should be calculated and recalculated multiple times in order to ensure results that are as precise and accurate as possible.

Multi-body dynamics

Electro-hydraulic drive systems often contain drive forces that are transferred from kinematic mechanisms directly to the various components of the machine itself. This is often the case with machines that have moving platforms, along with robots, presses and chassis. Multi-body dynamics are needed to ensure the stationary and moving components work in tandem as they should. This requires taking a number of variables into account, along with the interlinking of the different forces of the various drive units in order to make sure everything works as it should. Simulation software can play a significant role in ensuring that each component is designed to do exactly what it is supposed to.

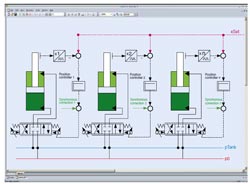

Fully-integrated system analysis

Simulation of electro-hydraulic drive systems includes an analysis of all the different systems and subsystems of a particular piece of equipment. Some of the things that need to be considered are the controls, mechanics and movement sequences of various parts in order to ensure they will all move perfectly in conjunction with one another. For very complex electro-hydraulic systems, this could require interlinking more than one simulation program together in order to duplicate a machine's exact functions. This can sometimes be a very time-consuming process, but is nonetheless very important in developing a system that performs the exact function it is designed to do.

Hardware-in-the-loop simulations

Electro-hydraulic drive systems make life easier for a number of people, and must be built reliably if they are to perform as intended. Hydac Technology employs all of the techniques described above to ensure that machine builders meet the required performance specification for the machinery or equipment being developed. Follow the link to find out more about the services and products available from Hydac.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>