Posted to News on 10th Nov 2007, 12:35

Improved efficiency for air-operated pumps

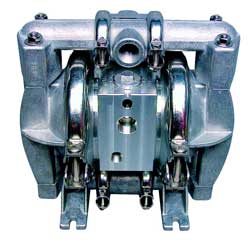

When it comes to energy efficiency, air-operated double diaphragm pumps are often criticised because of the costs associated with compressed air. However, users of Wilden pumps can now realise significant energy savings and lower operating costs by using the Pro-Flo X EMS system.

Available factory-fitted and as a kit for retrofitting, the Pro-Flow X EMS (efficiency management system) enables users of Wilden pumps to input specific operating parameters, thereby selecting the optimum balance of flow and efficiency for the application. The simple turning of the System's integrated dial changes relationship between the air inlet and the exhaust porting, with each dial setting between 1 and 4 representing an entirely different flow curve

Peter Carfrae, AxFlow's Wilden Product manager, explains: "The pumps leave the factory on dial setting 4, this being the highest flow setting. Moving the dial down progressively from 4 to 1 decreases the flow rate and, in turn, greatly reduces air consumption. Because most pump duty points are specified within the middle of the pump's flow capability, decreasing the flow to the actual duty point required using the EMS creates lower levels of air consumption."

Using Wilden pumps fitted with the Pro-Flo X EMS results in higher pump performance, air consumption savings that can be as high as 63 per cent over other types of AODD in certain applications, and improved operating flexibility. Wilden Metal EMS pumps containing the X prefix are all ATEX-compliant.

Carfrae states: "The new Wilden Pro-Flo X EMS is a measurable and quantifiable system that has been shown to achieve considerable air consumption savings over other AODD pumps. The system is available for pumps in sizes ranging 0.5inch through to 3inch and can be applied to pumps where users want to update existing installations and take advantage of the cost savings that can be achieved. Wilden will progressively supply all future pumps with the EMS as standard build."

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>