Posted to News on 16th Apr 2025, 14:00

Innovative clamping technology for the most stringent requirements

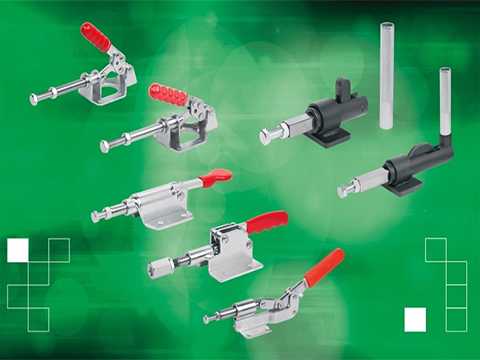

norelem expands its range of toggle clamps for demanding applications in metal machining and woodworking, as well as machine construction. The new clamping elements impress with a robust construction, flexibility, and high clamping forces of up to 33,350 N.

Toggle clamps from norelem are ideal for precise and reliable clamping and holding processes in production. They are used, for example, for securing workpieces during metal machining processes such as grinding, milling, or welding. In furniture making, they are used to hold wooden parts for sawing and planing, for example. They are also used in the electronics industry, in the assembly and mounting of printed circuit boards, electronic components and devices.

Sturdy, versatile, and flexible

Whether for welding, milling, or planning, toggle clamps from norelem offer high strength and stability. They operate on the basis of a thrust rod that is moved by means of a toggle joint. This motion generates the clamping force required to hold the workpiece securely. Most toggle clamps can be operated both by pushing and pulling, as they lock in both the closed and open positions. This flexibility makes it possible to adjust the clamps for different clamping tasks.

With 10 new families (05837-10 to 05837-28), norelem is now expanding its range of toggle clamps with forces from 500 N to 33,350 N, thus offering the right clamping technology for every application and optimally supplementing the existing range. The clamps are made of galvanised steel or type A2 stainless steel; the stainless steel variants are therefore non-corroding. Toggle clamps are durable and feature oil-resistant plastic handles.

User-friendly integration

The new toggle clamp variants are ideal for the fast and secure clamping and release of workpieces. In addition to mini and standard steel or stainless steel toggle clamps with clamping forces of up to 3,150 N and steel variants with a clamping force of up to 6,675 N, norelem also offers a pivoting version with a clamping force of up to 2,000 N. In addition, horizontal, weldable, and heavy-duty versions are available. All models can be mounted either by bolting or welding, allowing for flexible integration into existing systems.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>