Posted to News on 14th Sep 2021, 08:57

Inside view on hydraulic pump adaptors

Getting the most out of your machinery often depends on close integration between all components

An organisation that manufactures and integrates all the diverse components of a drivetrain provides the experience to help you select the best component combination for your application, states jbj Techniques.

Designed to meet the exacting safety standards of the offshore and chemical process industries, jbj Techniques produces adaptor kits certificated to Directive 2014/34/EU II2GD-IM2-TX -50 C< Service Temp < +105 C. Harmonised standards BS EN 1127:1, BS EN 13463:1, BS EN13463:5, BS EN 50303, BS EN 1834-1,BS EN 1834-3.

Generally manufactured in Cast or Nodular iron, bellhousings can be produced in steel, stainless steel or alternative exotic materials on customer request.

JXL pin and bush range

Couplings supplied for these applications are the jbj Techniques 'JXL' pin and bush range, which provide an anti-static and flameproof drive which meet zone 1 area requirements, conforming to all of the above standards.

Also available are spider and gear couplings, which are certified to zone 2 standards.

An important development of equipment for use within hazardous areas is the wet mount series of bellhousings. Commissioned to research and develop a product that would control the high temperature generated by a piston pump shaft seal when working within cycling applications.

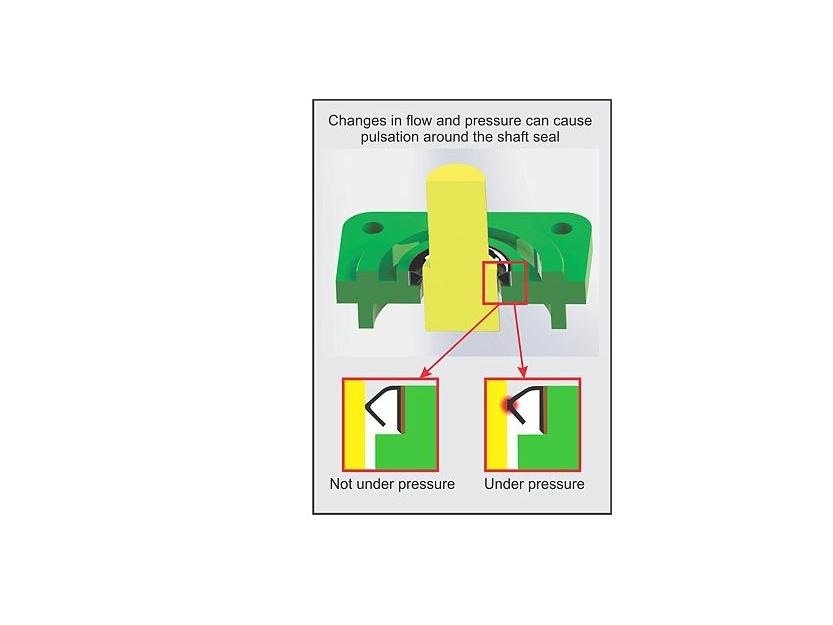

A little considered issue is the frictional heat generated at the shaft seal when the application requires the pump to cycle between different pressures, causing the seal temperature to increase.

Sealing the deal

This process will often take the seal temperature out and above the levels required by the relevant ATEX standards requirement. This specially designed assembly allows a pumped cooling flow to be passed over the seal face and through an auxiliary cooler. This, in turn, reduces the seal face temperature which can be maintained at an acceptable level.

With a vast array of components to select from, jbj reports that it is well placed to provide all required components to support the required cooling system.

28 Trowers Way

Holmethorpe Industrial Estate

RH1 2LW

UNITED KINGDOM

+44 (0)1737 767493