Posted to News on 30th Jan 2025, 13:00

I/O electronics for customised circuit boards

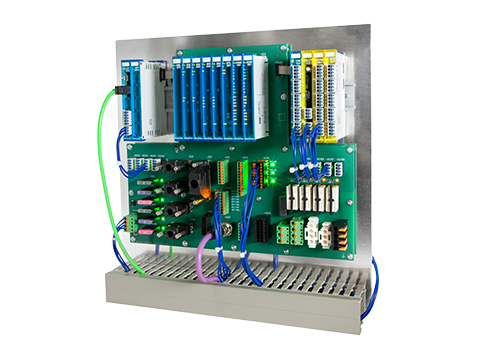

The X-DIAS I/O system from SIGMATEK expands the established S-DIAS automation system in the customer-specific printed circuit board (PCB) design. Series machine builders with medium and high volumes can flexibly integrate X-DIAS into individual circuit boards, saving wiring time and costs.

(See SIGMATEK at Machine Building North, 10 April 2025, on stand 4)

The new modular I/O series is based on the proven S-DIAS system, so it is just as robust and vibration-resistant. At 12.5 x 102 x 63 mm, the X-DIAS modules are even more compact in terms of depth.

Thanks to an electromechanical adaptation, it is possible to plug the modules individually and directly onto wiring boards.

The X-DIAS modules are equipped with a LED status display on the front and coding pins on the back. The appropriate drill holes are located on the PCBs at the corresponding module position. This mechanical coding prevents incorrect placement. In addition, any connectors, fuses, cut-off relays and the necessary intermediate wiring can be placed flexibly. On the wiring board, the bus and the bus supply are routed from one X-DIAS module to the next.

Save wiring time, minimise mistakes

Using wiring PCBs eliminates the need for manual single-core wiring, which saves a great deal of wiring time and expense. Cable harnesses can be pre-assembled, minimising the risk of wiring mistakes and significantly reducing the commissioning effort.

The X-DIAS I/O system can be combined with the S-DIAS system and the IP67-protected P-DIAS I/O modules, for example for variants of the basic machine or special options.

In addition to Industrial Ethernet VARAN, other bus systems can also be used for communication between the X-DIAS wiring boards and the control system.

X-DIAS modules can also be connected directly to the backbone bus of S-DIAS modules via a flat cable in connection with the S/X-DIAS adapter module AP 001. This direct connection reduces costs, since no field bus is required.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

SIGMATEK Automation UK Limited

24 Old Queen Street

SW1H 9HP

UNITED KINGDOM