Posted to News on 22nd Aug 2016, 17:21

Keeping control valves clean, inside and out

Modern hygienic fluid control applications demand very high standards in terms of cleanliness, not only for the components directly in contact with the process medium, but also for the external surfaces. Designing and installing complete fluid control systems that meet these stringent criteria requires expert design capabilities and innovative manufacturing facilities, as well as a considerable understanding of the applications. Ian Webster, Field Segment Manager, Hygienic Processing pharmaceutical at Brkert Fluid Control Systems, looks at the specific requirements of this sector and how they can be achieved.

Process control systems that operate in hygienic environments are subject to extensive levels of regulation and certification as well as regular audits to ensure continued compliance. In order to meet both current and some future regulatory demands, companies are well advised to carefully plan any new installations but also review more recent innovations that can be implemented on an existing manufacturing process.

Many hygienic processes will use a cleaning procedure, either clean-in-place (CIP) or steam-in-place (SIP), to maintain hygienic conditions within the process pipework and control valves. These processes can be largely automated and, providing the system has been correctly designed, very effective in disinfecting and cleaning process lines. However, the effectiveness of these systems is also reliant on valve design which should minimise internal volumes and avoid dead flow zones, which can hamper the cleaning process.

The excellent strength and cleanability of stainless steel makes it the material of choice for the vast majority of vessels, pipework and valves but achieving a high standard of cleanliness involves some refinement of the raw material. Some valves, such as Brkert's ROBOLUX design, use a system of electro-polishing, which involves the removal of 30um of metal from the media contact surface with a special electrolyte, under the effect of DC current. The material is removed without mechanical, thermal and chemical influences. As a result, the surface becomes smooth and shiny in the micro range; possible damaged outer layers are removed, and the properties of the pure stainless steel can be utilised.

In the past, the polishing process may have been completed by hand using small electric polishing wheels, which can be rather labour intensive and time consuming. This process is now automated and can also involve the use of an abrasive paste that is repeatedly pumped through the valve body in order to achieve a surface finish of less than 0.4um. This produces a very uniform surface which is then electro-polished to give a near mirror finish for all areas that come into contact with the process media. Using these processes it is possible to produce extremely smooth surfaces, even in complex valve arrangements, and this enables the CIP or SIP process to be effective.

Effective and efficient cleaning cycle

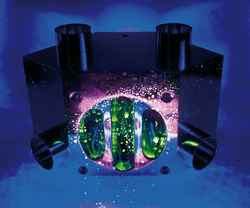

In hygienic applications where CIP / SIP are operated, it is essential to be able to ensure the cleaning cycle is both effective and efficient. In situations where larger-scale process equipment is being installed there will almost certainly be a factory acceptance test, part of which must demonstrate and document the effectiveness of the cleaning process. Brkert is able to test cleaning cycles and provide 100 per cent reliability on the flow properties and cleanability of a complete valve system by using a riboflavin test rig. As one of the few manufacturers of fittings and valve interfaces in the world that owns and operates such a test rig, Brkert ensures that the effectiveness and efficiency of each design is proven.

However, while the internals of a fluid control system is very important, the external equipment must also meet a number of demanding criteria in order to be deemed suitable for operation in hygienic applications. Valve positioners / controllers, sensors, control cabinets all play a role in the control system and as such need to be suitable protected against corrosion and cleaning processes.

Once again stainless steel is a dominant material, but this needs to be coupled with sound engineering design that minimises contamination of the local environment and can withstand regular cleaning processes that may involve high pressure water jets and cleaning chemicals. IP ratings, which indicate the level of protection against both solids and liquids, provide an independent assessment for each component, with IP66 and 67 being well suited to environments where regular cleaning takes place.

Brkert continues to develop innovative products designed to improve efficiency and reliability within a wide range of processing applications. With considerable expertise in designing everything from individual components to complete fluid control systems, Brkert offers turnkey products designed to meet the statutory regulations associated with hygienic processes. Go to www.burkert.co.uk for more information.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Fluid Control Centre

1 Bridge End

GL7 1QY

UNITED KINGDOM

+44 (0)1285 648720