Posted to News on 18th Jul 2013, 07:08

Machined compression and extension spring replaces wire spring

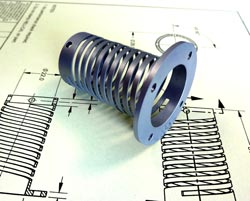

Abssac has designed and manufactured a machined spring to replace a wire wound spring that operates in tension and compression, resulting in improved performance and more efficient assembly.

While demonstrating the unique capabilities of machined springs, the question was asked: "Would Abssac be able to retrofit a spring now being used as a buffer spring in a fuel control system?"

The spring unit should compress and extend 2mm but deliver an accurate spring rate over a set lifetime. As the customer explained, the current wire wound spring was not providing an accurate spring rate over time and each spring had to be rate tested and certified before fitting; normal rate accuracies were ranging from +/-15 per cent and the spring rates were not linear.

As the name suggests, the machined spring is machined from a single piece of material. This not only allows one, two, three or more spring elements to be machined into the single part but, due to the geometry of the coil, the spring rate is linear. In fact spring rate tolerance can be as good as +/-1 per cent if required with machined springs.

After the preliminary discussion between the customer and the Abssac application engineer, a drawing of the concept spring was forwarded for review. A few minor changes were then needed, as the customer's engineer looked into incorporating attachment features within the single-piece stainless steel spring. Compared with the wire wound spring, all other dynamic parameters could be improved on, enabling a final configuration to be proposed.

Two test samples were sent to verify the installation and enable life testing to be completed. The machined spring supplied improved the efficiency of the application, reduced parts inventory and each spring supplied was certified on rate so it could be fitted straight into the application.

The success of the project has led to several other spring applications using the same physical configurations, but with varying spring rates and materials.

Follow the link for further information, an explanatory movie and more example applications of machined springs or telephone Chris Cattle on +44 (0)1386 421005.