Posted to News on 13th Aug 2014, 13:41

Modular valve body reduces energy needs and improves system flow

A new modular valve body design pioneered in Brkert's INOX range of space-saving modular valve bodies has increased the flow coefficient of a conventional angle seat valve, reducing energy requirements and improving system flow characteristics.

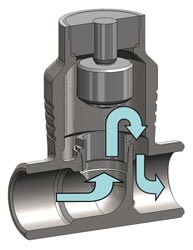

Valve systems used in the past for conventional piping are designed so that the inlet to the valve and the outlet from the valve are at one level. Inside the valve, the fluid flow is conducted through a seat, which requires redirecting the fluid three times.

This construction inevitably causes flow losses in the valve, which negatively affect the Kv value (flow coefficient for a valve) - a factor that must be taken into account when selecting and dimensioning a valve.

In the new, modular basic body, the inlet level and outlet level are separate. Since the fluid flow now only has to be redirected once through 180degrees, this increases the flow coefficient.

Separating the two levels also improves the design in other ways. The inlet and outlet level can now be connected directly with other valve bodies, without additional piping. The connections of the basic bodies can be assembled in a block and designed according to user-specific requirements. A pipe connection between the single valves is no longer necessary, since the fluid connection is established simply by joining the valve bodies.

This concept was developed under the premise of "mass customisation" so that it also allows the cost-effective production of customised products in small batches. In this case, several valve bodies can be joined to form a block using orbital welding technology. The result is a strong, compact block that can receive valve actuators and peripheral items direct to their own ports.

The bodies can be combined with standard Brkert valve actuator heads, which in turn can be used together with a position indicator or positioner. In addition, it is possible to integrate sensors for measuring flow rate, temperature and pressure. This approach is very flexible with respect to the connecting threads and connecting technology, so that it can be adapted to the requirements of each respective application.

Please visit www.burkert.co.uk to learn more about the modular valve body.

Fluid Control Centre

1 Bridge End

GL7 1QY

UNITED KINGDOM

+44 (0)1285 648720