Posted to News on 12th Apr 2021, 08:58

New, bespoke dust removal system

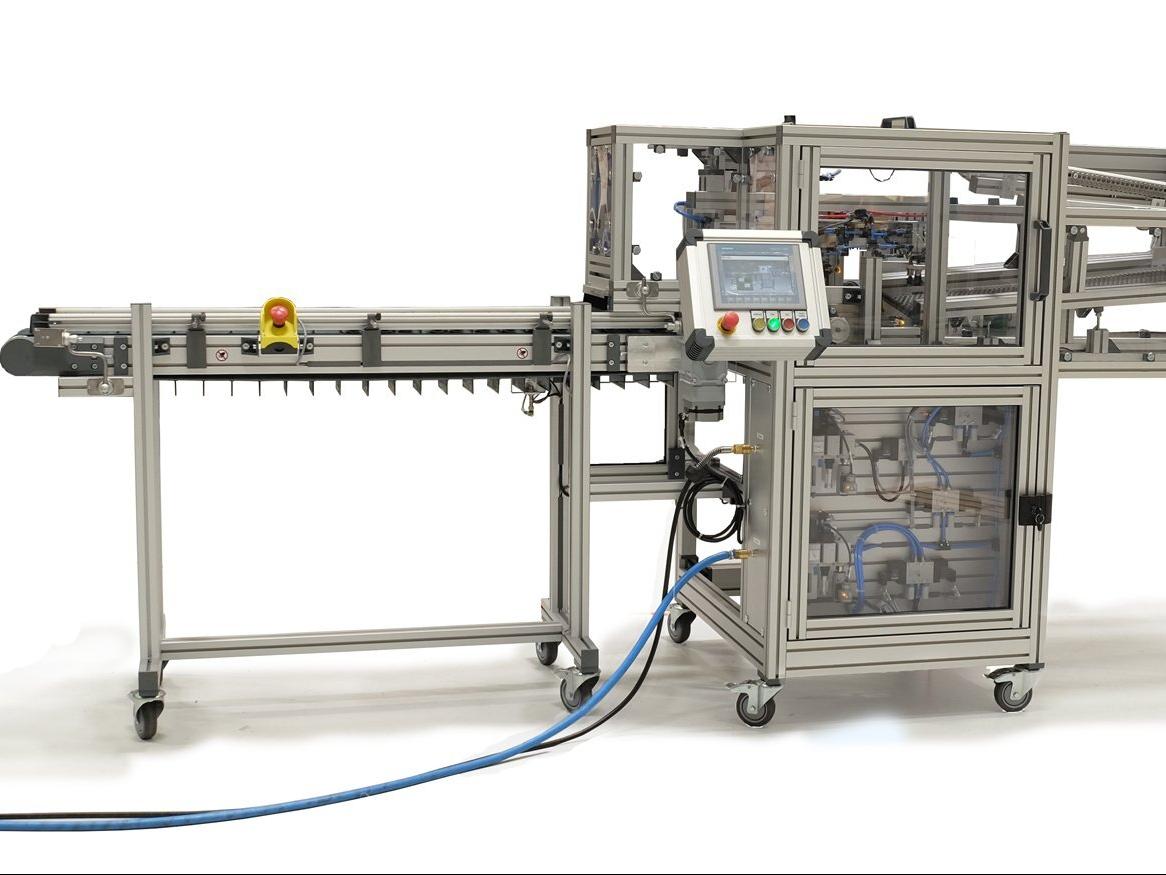

Cleaning contaminated pieces by hand can be a time-consuming process that is stressful for production, especially when large numbers are involved. MiniTec has designed, developed and built a solution

When large numbers of items are involved, hand cleaning takes time and can cause serious disruption to production schedules. It begs the question of how the cleaning of production pieces with constantly changing diameters and shapes might be automated: and preferably without time-consuming retooling. To this end, MiniTec has developed and manufactured a dust removal system for a customer that cleans a wide variety of production pieces without any of the previous time-consuming changeover processes. It also offers the advantage that the parts input supply and finished output is also integrated.

A wide variety of moulds can be fed, cleaned and discharged in this single MiniTec system. Currently, five different pieces are currently being processed with only two changeover units. The items to be cleaned are fed via a clocked rotary turret and an inclined plane, which cleverly enables the rolling of conical components without requiring a changeover of the feeder. A vacuum suction cup serves as a gripper, which is equipped with a spring-loaded thrust piece that adapts to any component diameter – removing the need for any unnecessary retooling of the gripper.

Rotating brushes and nitrogen

The cleaning process itself is carried out by using a rotating brush combined with the supply of nitrogen under pressure, where the worked pieces are blown off – compressed air is considered too impure at this point. A sensor continually checks the extraction system, only allowing the cycle to operate if the extraction is functioning, and the nitrogen is extracted together with the contaminants. Not only does this protect the system from contamination, it also, above all else, protects the employees.

To change over to a new batch, all that is required is an easy swap over to replace the guide brushes on the front of the cleaning station. The brushes on the side of the system hold the items in position so that the vacuum gripper can hold it and discharge it on a cycle belt. The webs prevent contact between the items and thus removes the likelihood of any damage.

The flexibility of the system is almost limitless, says MiniTec, with options to equip with rollers for simple repositioning, or it can be separated from the infeed and outfeed belts, resulting in the operation being more or less automated to suit the needs of a business.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Unit 1 Telford Road

Houndmills Industrial Estate

RG21 6YU

UNITED KINGDOM

+44 (0)1256 365605