Posted to News on 18th Oct 2015, 12:21

Portable generator uses hydrogen fuel cell and supercapacitor

A team from Imperial College London has developed a hybrid power generator comprising a hydrogen fuel cell and supercapcitor, controlled using a National Instruments CompactRIO device and software written with Labview.

Imperial College London is one of the world's leading science and technology universities. As part of the Energy Futures Lab at Imperial, students investigate low-carbon technologies such as hydrogen fuel cells (FCs) to address crucial global warming issues. Imperial Racing Green (IRG) is a student-led project at the university aiming to address these concerns.

Off-grid power generation - normally with diesel generators - is an area that has been identified as having potential to benefit from the more efficient and greener nature of FC technology. Diesel generators are typically used to supply off-grid electricity in locations where it is difficult and costly to install power lines, such as music festivals and remote construction sites. These generators are often inefficient, noisy and produce pollutants that contribute to climate change.

This was the motivation behind the development of the world's first zero-emission FC-supercapacitor passive hybrid power generator. A key part of halting climate change is educating the engineers of tomorrow and generating public consciousness of these green technologies, so the ICL team used the generator to power a band at a number of BBC events.

Besides off-grid power generators, IRG also develops zero-emission cars and motorcycles that race annually in the IMechE Formula Student event at Silverstone and the TTZero competition on the Isle of Man. In total, IRG involves over 100 undergraduate students from a variety of engineering departments at Imperial College London and has a central network of supporting PhD students and academics.

Application overview

The team started with a proton exchange membrane fuel cell (PEMFC) to achieve the goal of making a zero-emissions generator to advance research and awareness. A PEMFC is an electrochemical device that converts hydrogen and oxygen from the air into electricity and produces only water and heat as waste products. A PEMFC stack, where the chemical reactions occur, cannot operate on its own and requires a supporting system called the Balance-Of-Plant (BOP), which delivers the reactant air, hydrogen and cooling to the system.

In order to monitor the condition of the FC stack, sensors were needed to measure parameters such as pressure, temperature and relative air humidity, cooling, and hydrogen systems. Complete control over BOP components such as the blower, coolant pump, fan, recirculation pump and valves was also required to make sure they operated in the correct way.

At the centre of the monitoring and control system was a CompactRIO device, which featured a variety of available modules. FC stack pressure and temperature were measured using analogue input and thermocouple modules, and control was via a combination of relay and output modules. Finally, the CompactRIO FPGA and a CAN BUS module was used to rapidly access the 75 individual FC voltages that are critical for monitoring the health of the system. LabVIEW software was used to integrate third-party relative humidity sensors into the system using custom drivers, and the system was observed and altered as needed with PID control and PWM generation.

PEMFCs typically operate best under steady-state operation. Rapid transient operation can result in increased inefficiencies and lower durability. In order to improve efficiency and performance, the FC stack was passively hybridised with supercapacitors, which acted as low-pass filters to the stack and removed high-frequency load oscillations. The team chose a passive configuration because it removes the added mass, inefficiencies, and cost associated with active hybrid configuration. The whole system is separated into two main sections. The high-voltage system powers the inverter for the generator, and the low-voltage system powers the BOP systems during use and for startup/shutdown.

On the hybrid system, the CompactRIO device was used to monitor the voltages of the different devices as well as the currents through Hall effect sensors. Contactors enabled the isolation of different components during startup/shutdown and also acted as a failsafe. Alternative approaches to the CompactRIO system include microcontrollers such as the Raspberry Pi and Arduino systems. However, neither of these systems offers the rapid flexibility vital in the research and development of a teaching project such as this. The team also benefited by being able to easily manipulate data and visualise information in a clear format using LabVIEW.

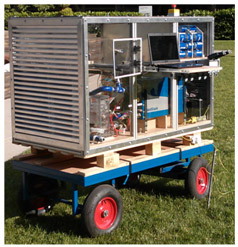

Through hybridisation of the FC stack with supercapacitors, the team gained a five per cent improvement in efficiency on the pure FC system. The supercapacitors provided a more steady-state environment under which the FC operated, which improved durability. These systems were integrated into a complete unit where the supercapacitor and power electronics sections were separated from the FC BOP components. The whole system was mounted in a wheeled enclosure for mobility. The result is the world's first zero-emission FC supercapacitor passive hybrid power generator.

ICL's team has displayed the zero-emission FC generator many times at public events where it can power a band to help promote green technology. Most noticeably, the generator was included in the BBC Energy Day, where the BBC 5Live radio studio was powered by renewables. It was featured on BBC Breakfast News and BBC Blue Peter and won the prestigious green Blue Peter badge.

The generator is continually being developed to include new and improved functionality. The reconfigurable nature of CompactRIO and LabVIEW are excellent for this application as well as other research and teaching programs. The team aims to keep working on this project and use it to generate more awareness of the global issues caused by climate change.

Follow the link for more information about the zero-emission FC-supercapacitor passive hybrid power generator.

National Instruments Corporation (UK) Ltd

Measurement House, Newbury Business Park

London Road

RG14 2PZ

UNITED KINGDOM

+44 (0)1635 523545