Posted to News on 23rd Nov 2012, 14:43

Push-pull chains for high loads and longer strokes

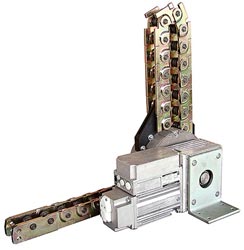

A major advantage of using chain to move a load is that it can be stored compactly but, until recently, chain could only be used in tension to apply a pulling force. However, the Framo Morat LinearChain Actuation System, which is available in the UK through R. A. Rodriguez, can be used to push loads as well, which makes it suitable for a wide variety of industrial applications.

Push-pull actuation using chain is commonplace in theatre engineering, where the loads are exceptionally high. Framo Morat has now developed the concept to provide it with much wider commercial appeal: stroke lengths of up to 30m can be supplied, with a maximum push force of 35,000N for a single chain - though multiple chains can be used where higher loads are required.

A special profile with interlocking fingers enables the chain to become a rigid thrust device for pushing a guided load, such as on a linear slide or a rail. Unloaded LinearChain rolls up into a magazine, so the product is particularly suitable for applications requiring long strokes where space is at a premium. It also achieves high positioning accuracy, has a constant stroke speed, provides smooth, shock-free motion, and it has no elastic hysteresis under load.

The compact nature of LinearChain is proving to be one of its main selling points; when compared to alternative methods for pushing a load. For example, if a cylinder is used, the design envelope needs to be twice the length of the stroke to account for the piston rod when it is extended. Or, if the load is mounted on a carriage with driving wheels, a power pack and electrical or hydraulic services need to be accommodated too. Not only does this make the resultant system cumbersome and bulky, but it also prevents its use in harsh environments.

LinearChain can be unfurled through a gap measuring just 100mm square. It can also be fed from a vertically-mounted magazine. In this way substantial lengths of chain can be stored and turned through 90 degrees on a sprocket to provide long-stroke linear motion.

It can also be used in temperature extremes, from -50 to +600degC, which makes it suitable for use in equipment such as heat treatment furnaces (annealed steel chains are available for such applications).

Another important point to note is that LinearChain is electrically driven, so implementing a control system is straightforward, and the resultant actuator is very manageable.

Application examples

A new scissor lift for aerospace manufacturing and maintenance is another new LinearChain application for which hydraulic rams were initially considered as a method of actuation. This is a common choice for arduous lifting tasks, but the size of the rams and the need for additional support equipment ruled them out for this compact design. Thanks to the compact nature of the LinearChain, the platform could be designed with a very low start position, which makes it easy for engineers to step on and off while carrying equipment.

Paul French of R. A. Rodriguez explains: "By using the Framo LinearChain, the customer can achieve a much more streamlined and lightweight construction and is able to effect a straight line. A hydraulic ram by comparison would be a much bulkier and heavier mechanism in order to push the geometry of the scissor lift."

In this instance, the Framo LinearChain was specified as a standalone unit due to the high torque requirements of the application (3700Nm). In most cases, R. A. Rodriguez supplies the LinearChain with the complementary Compacta slip-on geared motor that has a maximum torque of 1600Nm and is suitable for most push-pull applications.

Paul French concludes: "Not only did the Framo LinearChain meet the design and performance needs of the application, it was also a cleaner solution and a much more cost-effective method of actuation too."

Follow the link for more information about the Framo Morat LinearChain Actuation System from R. A. Rodriguez.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>