Posted to News on 21st Oct 2022, 09:10

Safely automated in compliance with standards

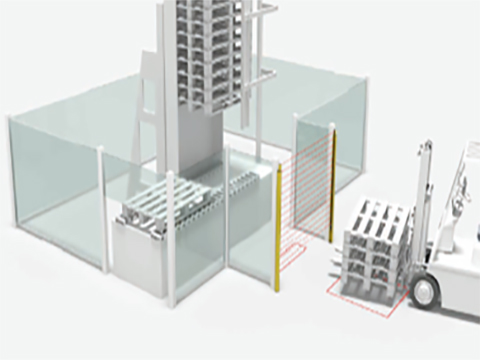

A new safety solution for palletisers and depalletiser using induction loops, light curtain and monitored signal sequence satisfies the requirements of revised standard EN 415-4, thereby ensuring maximum safety. Leuze has produced a new Technology Report detailing this new safety solution.

In this solution, the induction loops are not located in front of the danger zone. Instead, one is located outside of the danger zone and the second is located behind the electro-sensitive protective equipment, ie within the danger zone. The ESPE – the optoelectronic protective device – also remains in its traditional position. It separates the traffic zone and danger zone. In addition, there is also a safety system that monitors a defined sequence of signals and initiates the automatic restart.

In operation, if the presence of a forklift truck is detected by the induction loops and if the forklift then correctly executes the specified process sequence, the safety system initiates the automatic restart of the work process.

As a ready-to-use system, the solution from Leuze can be used immediately after installation. System owners are, thus, always on the safe side and already satisfy the requirements of the future EN 415-4 today.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

1B Fenice Court

Phoenix Park

Eaton Socon

PE19 8EW

UNITED KINGDOM

+44 (0)1480 408500