Posted to News on 15th May 2025, 10:00

Safety curtains to protect operators from caustic wash tank

When an automotive Tier 1 producer of metal assemblies needed a reliable and robust machine safety guard to protect operators from possible injury while the degreasing is in progress, it turned to Contrinex.

The manufacturer of automotive stamped, machined and assembled metal parts, needed to ensure that prior to assembly, all parts are free of lubricants used in their production or as a surface protection. A degreasing tank is very effective at removing all traces of lubricant and protective coatings, and is therefore, an essential stage of the manufacturer's process.

Degreasing tanks contain caustic fluids commonly held at high pressure and/or high temperature. Therefore, some aspects of this process are potentially hazardous to both employees and the environment. The high temperature and pressure at which cleaning takes place means that anyone accessing the tank while the process is running, risks injury from caustic spray and harmful vapours.

The containment method chosen must take account of the need for human interventions, while ensuring operator safety. Gates and electromechanical interlocks were considered, but as the tank is over 3m wide, mechanical gates would be large and therefore slow and cumbersome to use. A simpler, robust, reliable and more operator-friendly solution, was sought, that would still minimise liability costs and the loss of process fluids.

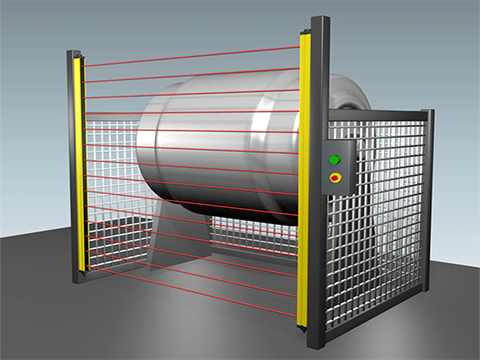

Contrinex's YBB safety light curtains proved ideal for this application, because of their ease of installation in addition to their meeting safety Category 4 of EN ISO 13849-1, and Type 4 of DIN EN 61496-1 and -2.

The safety light curtain comprises a sender and a receiver unit, generating a curtain of infra-red light beams, spaced at 30mm to detect an object the size of a hand or bigger. LED displays on the sender and the receiver indicate detection field status, operating mode, transmission channel, and alignment quality.

A light curtain featuring numerous light beams over a protective field height of 1.8m is used to ensure that an operator cannot access the hazardous area by reaching over, or under the light curtain. Similarly, the light curtain is mounted on the edge of metal-mesh guard panels so that an operator cannot reach around the protective safety light curtain.

The safety light curtain detects access to the tank's lid and thus prevents the operator from opening them while cleaning is in progress. Any person or object entering the protective field will not only disable the tank's spray jets and stop agitation, but will also cause the control system to idle before allowing the lid to be opened.

The use of safety light curtains rather than doors with safety sensors fitted, offers good access to the tank for operators to load and unload, and they also provide an unobstructed view of the tank.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>