Posted to News on 1st Jun 2022, 09:13

Schneider Electric launches digital twin software solution

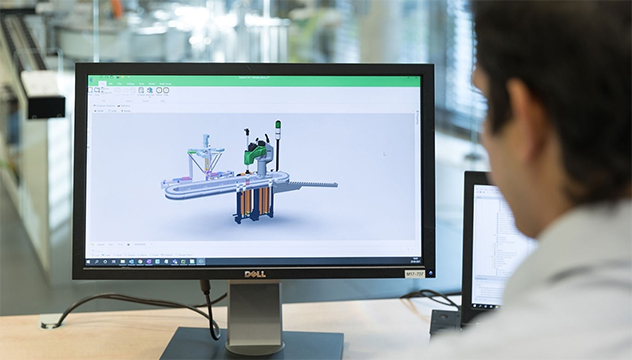

Schneider Electric has launched EcoStruxure Machine Expert Twin, a scalable digital twin software solution to manage the entire machine lifecycle.

The software enables OEMs to create digital models of real machines so they can be designed and commissioned virtually before building the machine itself. EcoStruxure Machine Expert Twin’s intuitive environment includes drag-and-drop mechatronic components, VR/AR interfaces, and application-focused libraries, all of which enable the parallel engineering of mechanical, electrical, and control tasks.

The solution’s open programming environment allows for add-ons and extensions, with a multitude of advanced modules and seamless integration into EcoStruxure Machine Expert and EcoStruxure Machine Advisor, as well as adaptation to customer data sources, workflows, and processes. EcoStruxure Machine Expert Twin helps OEMs to improve design processes and quality and minimise commissioning costs. It also provides an entirely new level of flexibility and efficiency in operations and maintenance.

“Digital twin software is paving the way for new machine designs, creating more agile production, and increasing machine performance,” says Ali Haj Fraj, senior vice president for digital factory at Schneider Electric. “Smart manufacturing allows for greater productivity and flexibility. Designing the future of manufacturing with EcoStruxure Machine Expert Twin can give OEMs a faster time-to-market, less risk of malfunction, and machines that are truly fit for purpose.”

Using EcoStruxure Machine Expert Twin, Schneider Electric says customers can expect:

- A 60% savings in commissioning time

- Up to 50% faster time-to-market

- Up to 20% savings on quality costs through testing before and during commissioning

- Revolutionise the design process

EcoStruxure Machine Expert Twin spans the entire machine lifecycle, from sales, concept, and design, to manufacturing and operation. Transforming design ideas into convincing sales animations helps customers to properly visualise the end product, while the in-depth design helps to improve and verify prototypes, reduce risk and quality costs, and speed up time-to-market.

The company says EcoStruxure Machine Expert Twin revolutionises machine building by digitising all the processes, from a detailed design to the mechanical, electrical, and controls, allowing for virtual test strategies and commissioning, as well as shortened factory acceptance testing. The solution also improves system integration tests, increases software quality, speeds up production ramp-up, and saves crucial onsite commissioning time.

EcoStruxure Machine Expert Twin can also open new revenue streams for OEMs over the complete machine lifecycle through machine servicing, operator training, and further improvements and upgrades. The software enables OEMs to offer new services based on digital twins, improve and test software upgrades virtually, and reduce machine downtime.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>