Posted to News on 16th Jan 2007, 20:53

See new bearings and energy chains at Machine Building Show

igus UK will be showcasing new high-performance tribo-polymer bearings, energy chains and cables on stand G11 at The Machine Building Show (NEC, Birmingham, 25/26 September 2013). Visitors to the stand will be able to see live demonstrations of the company's industry-leading maintenance-free bearings, as well as its energy chains and chainflex continuous-flex cables, which are cost-effective and reliable for machine builders. Visitors will also have the opportunity to meet polymer experts to learn how to optimise processes and reduce costs through the innovative use of plastic components.

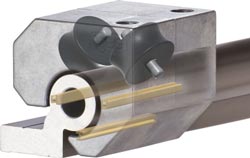

Two of the products highlighted on the stand will be the WJRM double hybrid bearing (pictured) and the R4.31 energy chain. igus drylin high-performance polymer bearings are maintenance-free and need no further lubrication over their entire lifetime. The bearings give excellent friction and wear values, and are resistant to dirt, water, chemicals and extreme temperatures, making them an excellent choice for machine builders. igus has a bearing life calculator on its website so that an accurate prediction of bearing life can be made easily and quickly.

The WJRM hybrid bearing offers a combination of roller and plain bearings, and is suitable for use on sliding machine tool doors, machine guards and control panels. By using the WJRM bearing, doors glide simply with minimum force thanks to the maintenance-free roller that supports the door's weight. The product's smooth-running design also features sliding pads made from the proven iglidur J plastic bearing material, which absorb shear and misuse forces; these run on a rail made from hard-anodised aluminium. A new version, the WJRM double hybrid bearing, features twin rollers with axes at 90 degrees to each other, which share the vertical load and also help to support offset loads better than the single-roller version.

In industries such as automation and materials handling, linear bearings that are exposed to swarf and debris can become jammed and, at worst, lead to production line failure. igus has an extensive range of robust linear guide systems that are resistant to detritus, maintenance-free and never need relubrication, thereby providing an extremely cost-effective alternative to conventional metal-based bearings.

Energy chains and cables

igus has been developing its cables for over 20 years and its chainflex cables have been designed with demanding moving automation applications in mind, giving reliable performance with high cycle rates, compact design spaces, and very small bending radii of as little as four times the outer cable diameter.

Experts from igus UK will be on hand to provide advice and guidance on selecting energy chains, bearings and cabling assemblies for specific application. To arrange an appointment, call Leanne Golding on +44 (0)1604 677240 or email [email protected].

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>