Posted to News on 14th Feb 2022, 08:57

Smart actuators provide an all-in-one linear positioning solution

Applied Motion Products (AMP) has released a new line of linear actuators based on its StepSERVO integrated motors as all-in-one linear positioning solutions including closed-loop motor and drive, motion controls and comms.

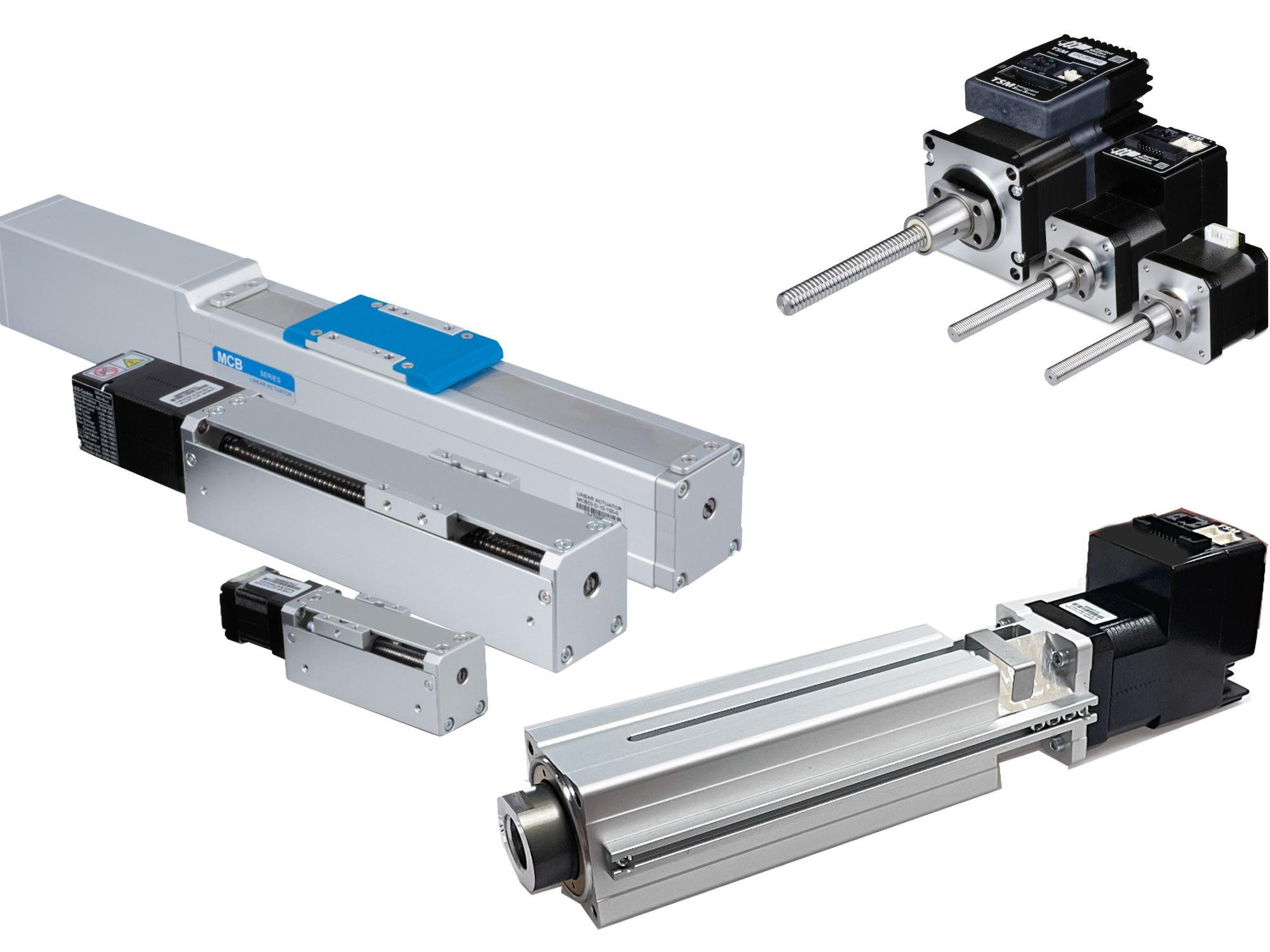

Available from Mclennan, AMP’s European distribution partner, the new StepSERVO Smart Actuators are variously available with NEMA 11, 14, 17 or 23 frame motors configured with built-in ball or lead screw mechanics. The MLA and MCB series are moving carriage designs, while the MLT series is a pushrod-style actuator.

“AMP’s well-proven StepSERVO technology combines a digital closed-loop servo drive, encoder feedback and several options for motion control and communications in a single integrated package that delivers more torque, acceleration, speed, accuracy, and efficiency over conventional open-loop stepper motor systems,” states Mclennan.

Actuators based on AMP screw motors

The new compact and space-saving actuators are based around AMP’s wide range of screw motors - hybrid stepper motors where the standard motor shaft is replaced with a lead screw assembly. MLA- and MCB-Smart series linear actuators feature an extruded aluminium rail and support system with a moving load carrying carriage. These versions are available in NEMA frame motor sizes 11, 14 and 23.

Users can choose various ball/lead screw pitches and nut material options with leads from 1 to 10 mm to suit their positioning resolution and speed requirements – speeds up to 100 mm/sec are available. The largest actuator, with its 23-frame motor, has a maximum stroke of 250 mm and a maximum load capacity of 7 kg horizontal and 4.4 kg vertical. The direct integration of the screw into the motor allows a coupling-free design that saves space for a more compact solution. The MCB version includes a dust seal and fully shrouded motor whilst the lower cost MLA offers is an open-frame housing design for use in clean environments. Both versions include mounting fixtures.

The MLT series pushrod style actuator is also based around the AMP’s Screw Motors in NEMA 11 or 17 frame sizes. “Well suited for miniature push, pull, lift and press applications, a choice of lead screw or ball screw mechanics provides users with a wide scope of cost vs. performance options,” adds Mclennan. “The largest MLT actuator can deliver a thrust force up to 300 N and speeds to 250 mm/sec with low vibration and low noise operation.” AMP’s Screw Motors are available as separate components without StepSERVO for use with independent drives and controls.

Closed-loop stepper technology

The new StepSERVO Smart actuators utilise AMP’s closed-loop stepper technology for direct on-board motor drive, programming and optional networking. This decentralised approach is said to see benefits in reduced installation cost through minimised machine wiring, faster machine build and design time, and a control concept that is complementary to Industry 4.0.

The new Smart actuators are available with a wide choice of control options, including step/direction, +/- 10V DC torque/velocity and positioning, as well as AMP’s Q Programming which provides streaming commands with maths and machine I/O control functions. RS232 or RS485, Modbus RTU and CANopen communications are on hand, as well as EtherNet/IP and Power over Ethernet(PoE). The 23 frame StepSERVO can be supplied with absolute encoder feedback. AMP’s StepSERVOs are also available as separate integrated motors with these options in NEMA frame sizes from 11 to 34.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Unit 1, The Royston Centre

Lynchford Road

GU12 5PQ

UNITED KINGDOM

+44 (0) 1252 531444