Posted to News on 10th Feb 2021, 08:59

Standards compliant guarding for new laser cutting machine

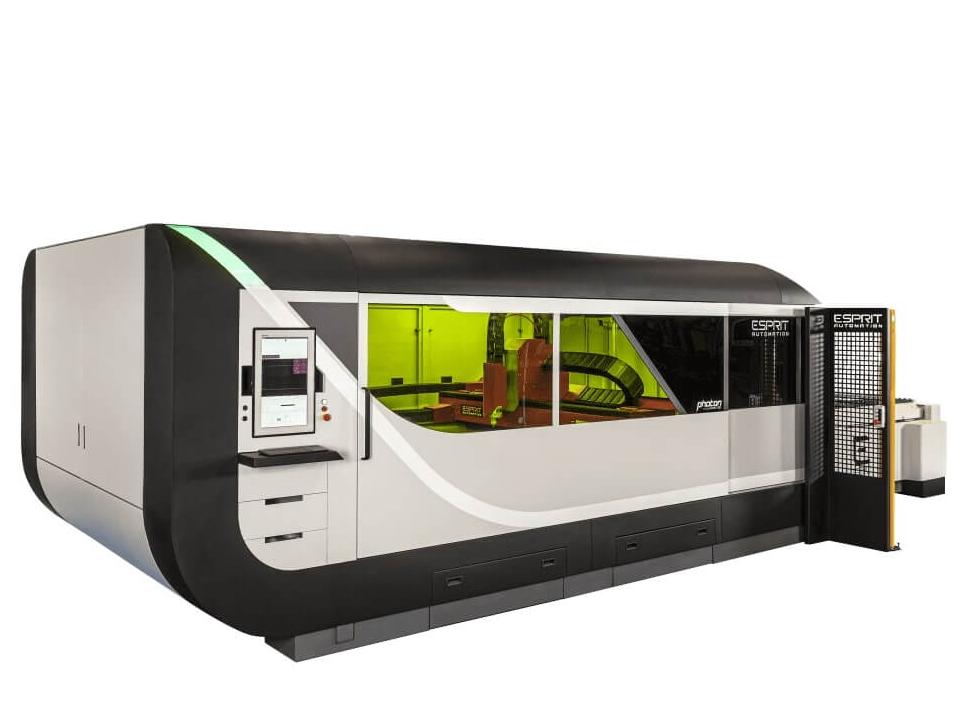

Procter Machine Safety has designed standards-compliant guarding for a new laser cutting machine and is now manufacturing multiple sets of guards for its customer, Esprit Automation Ltd

The challenge

Esprit Automation is widely experienced in cutting technologies for metal sheet and plate and produces a market-leading range of CNC cutting machines. To date these have been ‘open’ gantry-style machines, but the company’s new Esprit Photon 5G high-performance fibre laser cutter is fully enclosed. Esprit Automation has limited knowledge of machine guarding standards and the design of sheet metal enclosure guards, and whilst the business manufactures most components for its machines in-house, it did not have the capacity to produce large machine guards.

The solution

After considering its options, Esprit Automation decided to subcontract the guarding to Procter Machine Safety. Esprit’s design team already had a concept for the guarding, so Procter’s designers took this and developed it into a full set of detailed drawings for a sheet metal enclosure guard that has the right aesthetics whilst also being standards-compliant and ergonomic. It also had to be cost-effective to manufacture as well as straightforward for Esprit Automation’s fitters to install at the customer site. Overall, these are large machines, with the guards measuring 5.7m long by 3.2m high wide and 2.3m high.

The detail

Procter Machine Safety undertook the detailed design, including providing mounting points for the interlocks specified by Esprit Automation. The concept for the guarding included curved sections and a two-tone finish that Procter applies using its in-house polyester powder coating facility. A 3.3m wide sliding door at the front of the machine gives the operator clear access, and this door features a large viewing panel. Because of the mechanical hazards and bright light emitted from the laser cutting process, the glass is toughened, laminated and tinted. To minimise the effort required for the manually operated door, it runs on high-specification linear bearings. A pneumatically powered rise-and-fall allows the machine’s moving table to slide in and out for sheet or plate to be loaded and profiles to be removed. At the opposite end, a pair of interlocked hinged doors provides additional access, and panels on the rear and roof can be removed when required for maintenance. There are also two trays under the machine that pull out from the front.

Procter’s designers incorporated a control panel that is mounted on an articulated arm so the panel can be manoeuvred to a convenient position or pushed back until it is flush with the front of the machine. Below the control panel, the guards house a slide-out keyboard and three storage drawers. Because of the high speeds and accelerations achieved by the Esprit Photon 5G, it was necessary for the guards to be sound-proofed to minimise noise emissions and ensure a comfortable working environment for the machine operator.

Esprit says that its Photon 5G has been extremely well received by the marketplace and the case study here relates to a follow-on order for two sets of machine guards. As Procter Machine Safety had already programmed its own CNC laser cutting machine, punch press and folding machine, these programmes were retrieved from the relevant libraries. The guards were then fabricated, trial-assembled, dismantled, and prepared and finished in a tough polyester powder coating. Finally, the component parts were built up into sub-assemblies, quality checked, and packaged ready for despatch to meet Esprit Automation’s build schedule.

In conclusion

Thomas Shapland, Marketing Director of Procter Contracts, concludes: “By subcontracting the guarding design and manufacture to us, Esprit Automation is benefiting from our in-depth knowledge of machinery safety standards, as well our expertise in the production of high-quality, ergonomic guarding. Furthermore, Esprit Automation’s design engineers are not side-tracked from their core competencies, and the production team can remain focused on higher-added-value tasks relating to cutting technologies. Importantly, the quality of Procter’s guards ensures the flagship Esprit Photon 5G has the right aesthetics to impress prospective customers too.”

More information about sheet metal guards may be found here. Or contact Procter Machine Safety by emailing [email protected] or telephoning them on 02920 855758.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>