Posted to News on 5th Oct 2022, 10:30

The future of the assembly line with Liberty Reach

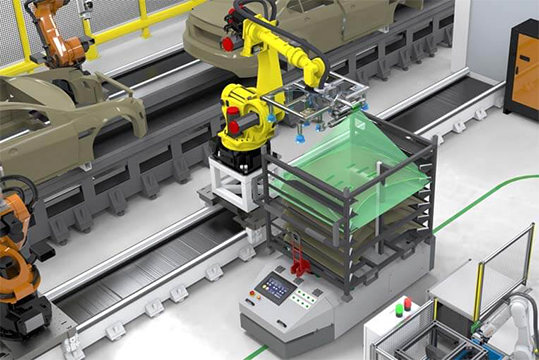

Using rugged computers from OnLogic to provide the required reliability and connectivity on production lines in the automotive sector, as well as installation flexibility, Liberty Reach is adding the intelligence to ‘smart manufacturing’.

The automotive industry has led the way in ‘smart manufacturing’ from the very start, with the Ford assembly line, quite literally, putting the first pieces together in 1913. With Industry 4.0 ushering in a new era of connected machines, the modern factory is more efficient, more versatile and safer than ever before.

Ensuring that equipment, operators and even the factory environment itself, remain productive, however, relies on a new breed of vision-based robotics. Liberty Reach, an industry leader in providing 3D volumetric sensors, computer vision algorithms and architectures for robotic manufacturing processes, works with many of the biggest names in the automotive sector, including General Motors, Tesla, Toyota and Ford Motor Company.

Libery Reach uses custom proprietary OnLogic hardware as a controller for its robotic guidance machine-vision systems. These devices, paired with robot arms and other equipment, are helping manufacturers not only assemble the next great automobile, but also build the future of the assembly line itself.

The basis of Industry 4.0 is intelligent devices making informed decisions about how to optimise actions and processes to save time and money while also protecting workers from the more dangerous aspects of large scale manufacturing.

With so much at stake, reliability is paramount. In addition to the potential safety hazards of robotic equipment failures, every minute of downtime can cost an auto manufacturer thousands of pounds. Rugged computers from OnLogic keep the line running smoothly.

“Our clients’ work involves the tightest manufacturing tolerances with no room for variance or downtime, which is why we’ve partnered with OnLogic for our robot guidance machine-vision systems,” said Brandon Schmalzel, engineering manager at Liberty Reach. “OnLogic helped us find a custom solution that accommodates the PoE, graphics, and power input requirements our customers demand, all in a small and rugged form factor that stands up to harsh industrial environments.”

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>