Posted to News on 8th Apr 2016, 12:11

UV/light cure masking resin: protection for turbine components

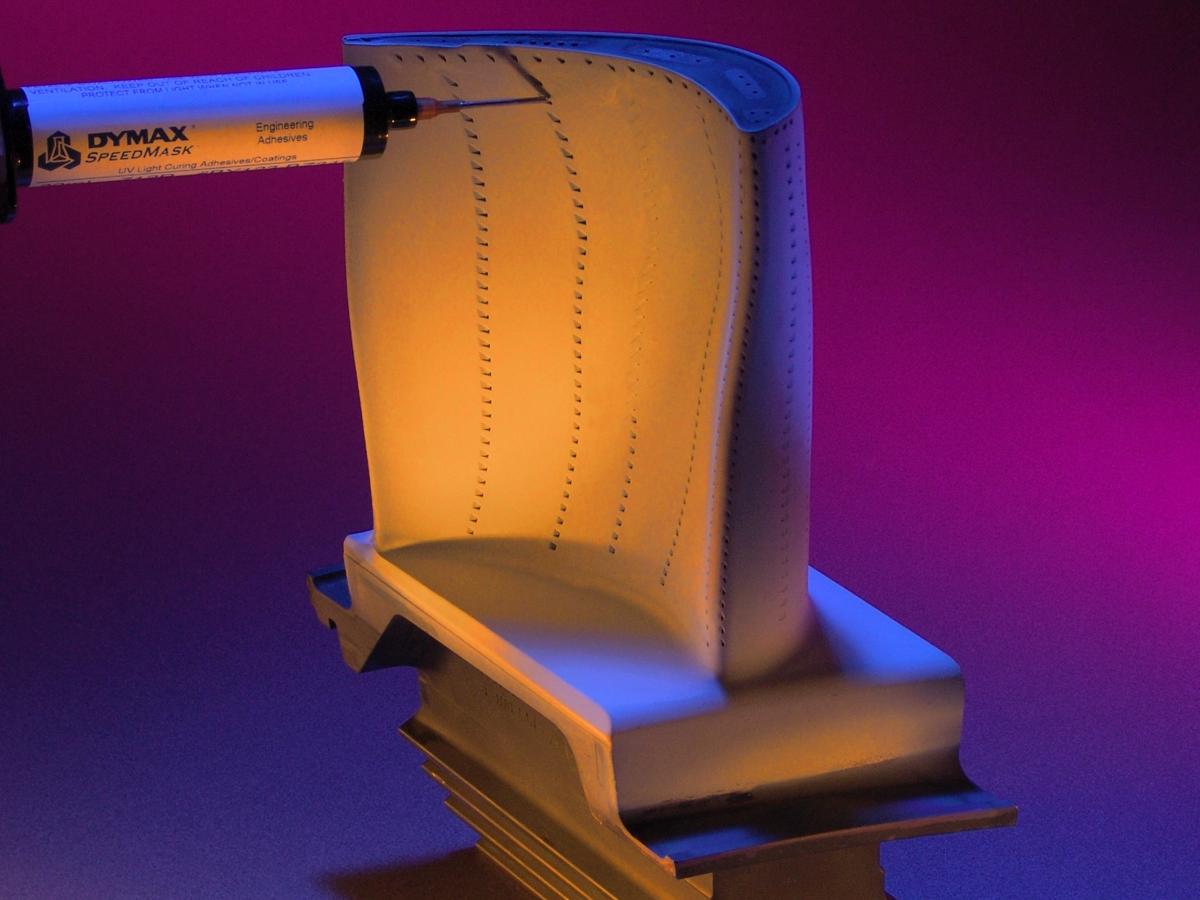

Intertronics' recent introduction of DYMAX Speedmask 718 UV/light cure masking resin brings the benefits of reliable, quick, effective application and simple removal, to the protection of turbine blades, vanes and other components during specific area surface treatments such as APS and HVOF coating.

Protecting areas being left untreated is crucial to high-quality outcomes with these high-performance parts where Speedmask 718 provides excellent temporary protection for surfaces and cavities - so enabling the processes of manufacture, overhaul, repair and rework that have been far more difficult in the past using other traditional means.

Speedmask 718 is readily applied and cures quickly when exposed to UV/Visible light forming a hard durable, protective covering on many surfaces, including nickel alloys and high temperature steel. It can then be cleanly removed from the substrate by incineration at over 650degC, leaving a light ash which can be readily disposed of.

Please follow the link for further information about DYMAX Speedmask 718 UV/light cure masking resin.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>