Posted to News on 5th Oct 2007, 07:48

Versatile safety systems used in machine upgrade and new-build

Jokab Safety has supplied a number of its high-integrity machinery safety monitoring, safety PLC and safety I/O products to enable SysCom UK to upgrade two manufacturing cells and safeguard a third.

GPS is part of one of the world's largest manufacturers and suppliers of high-performance plastic piping products and fittings for the water and gas industries. In 2003 the company acquired two manufacturing cells that needed to be refurbished and brought up to the current safety standards. SysCom UK was brought in to evaluate the machine guarding and, where it was needed, to increase the safety integrity. Having looked at the options, it was decided that the manufacturing cells needed to be brought up to BS EN 954-1 Safety Category 4, BS EN 62061 SIL3.

The cells consisted of a gantry robot and an injection moulding machine, together with other automated processes. The focus was to prevent operators accessing the manufacturing cell during production and to fully integrate all of the safety devices from different areas of the cell.

SysCom UK had decided to use the Vital system from Jokab Safety, as it met the Category 4 requirements and enabled all the devices to be connected to one safety monitoring unit; this presented space-saving and cost-reduction possibilities for both SysCom UK and GPS. At the same time, Vital fitted in with the requirement for a centralised control architecture.

Safety I/O

The safety system consisted of emergency stop buttons and Jokab's JSNY9 door interlock switches. These devices had Tina 3A interfaces installed to monitor the two normally-closed contacts and change the signal to the Vital unit, should the safety devices be operated. Where it was not possible to use the Tina 3A, the Tina 7A was utilised, which has the same functionality.

A Spot 10 safety light beam was included in the safety system to monitor the gantry robot position. In order to simplify the connection of all the devices, SysCom UK added some Tina 4A connection modules, which allow all the safety devices to be taken to one point before connecting to the Vital Controller.

After the manufacturing cells had entered full production, GPS added a third cell. Once again, Jokab Safety's Vital system was specified and installed.

New cell, new requirements

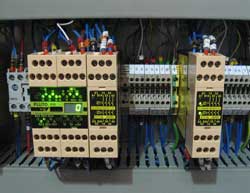

During 2007 a new manufacturing cell was designed by SysCom UK and the automation systems were different to those of the previous cells. Jokab Safety were called in to look at the machine safety possibilities. The interlocking and reset requirements in the new cell were more complex than the previous systems and, in order to meet these requirements, the Pluto safety PLC was deemed to be the best option (see photo).

Pluto enabled SysCom UK to still use the Tina interfaces, as per the Vital system, as Pluto can utilise three dynamic pulse outputs. In other words, it could be seen to have three Vital units inbuilt. The main benefit is that Pluto is a fully programmable safety PLC system, therefore any interlocking for the failsafe outputs or complex reset requirements could be handled easily. Pluto also offers the flexibility for making changes to the safety system without any major wiring changes in the control panel.

GPS and SysCom UK are very satisfied with the quality and product support from Jokab Safety and are currently investigating other possibilities for future projects.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Tower Court, Foleshill Enterprise Park

Courtaulds Way

CV6 5NX

UNITED KINGDOM

+44 (0)2476 368500